2025-07-09

When the TPU laminating machine is running normally, check the tightness of the fabric and check the product. Initially determine the tension of the composite fabric, then cut the sample and inspect the fabric. If just stop for a day or two, just turn off the metler. If stop a few days more, when cooling down, use lubrication high temp resistant grease(above 200 celcius degree) to seal the below glue hose gun head.

How to operate TPU laminating machine?

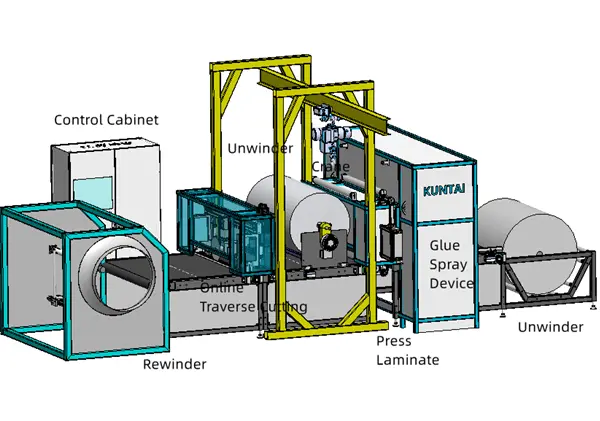

TPU laminating machine has a wider and wider application nowadays. It has extended from garment laminating into mattress protector laminating and blackout curtain fabric laminating and now to advanced textile laminating technology. TPU membrane development has played a great roll in this process. A variety of TPU film thickness and capacities make TPU laminating machine more and more popular. While, how to operate TPU laminating machine? Let us focus on this topic today. First of all, to decide which material to apply glue to. If you want to reduce glue quantity and get soft laminated final product, you can apply glue onto TPU and then laminate it with fabric on the TPU laminating machine. If you want super strong bonding, you can apply glue onto fabric and then laminate it with TPU.

When the TPU laminating machine is energized, check the air compressor source, start the oil heater, press start button of the melter, run the gluing roller, set the speed of about 5Hz and wait for the oil temperature to reach the required figure.

Get through TPU laminating machine the TPU film and fabric,and when the required temp is reached, close the gluing gap and start the glue transfer. Pull fabric by guide rollers to rewinder of the TPU laminating machine, pull the film to the gluing gap. First stop the gluing roller, start the machine, click the acceleration button, close the gluing gap and pressing gap, glue begin to transfer to the film, then drag the film into the laminating gap, lamination pressure roller is closed, film and fabric lamination. After cooling roller, cooling pressure roller in the film and cloth lamination according to the fabric requirements choose closed or open state. When the laminated part reaches the rewinding part of the TPU laminating machine. The machine operates normally and then increases the speed.

Get through TPU laminating machine the TPU film and fabric,and when the required temp is reached, close the gluing gap and start the glue transfer. Pull fabric by guide rollers to rewinder of the TPU laminating machine, pull the film to the gluing gap. First stop the gluing roller, start the machine, click the acceleration button, close the gluing gap and pressing gap, glue begin to transfer to the film, then drag the film into the laminating gap, lamination pressure roller is closed, film and fabric lamination. After cooling roller, cooling pressure roller in the film and cloth lamination according to the fabric requirements choose closed or open state. When the laminated part reaches the rewinding part of the TPU laminating machine. The machine operates normally and then increases the speed.

Wechat: ANNIELV88

Wechat: ANNIELV88