2025-08-05

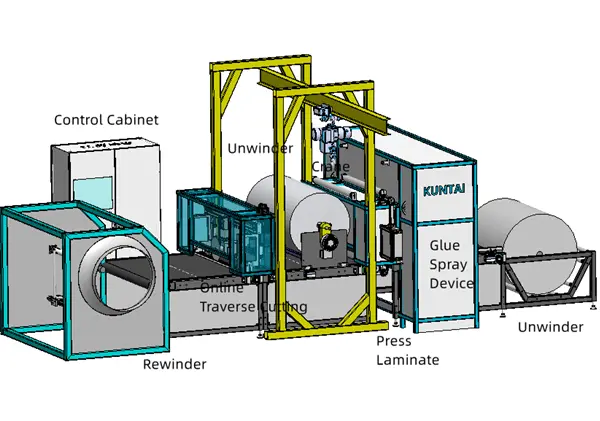

Working principle and technical advantages of Double Belt Press laminating machine in car interior industry: The working principle of the double belt press laminating machine is mainly based on hot pressing technology. Through the action of heating and pressure, different materials (such as paper, wood, plastic film, resin, fiber, etc.) are pressed together with adhesives webs or hot melt film or hot melt powder or materials its own thermal capacity to form a sturdy board structure in high temperature and high pressure environments. This composite/laminating technology has significant technical advantages: 1. Accurate temperature and pressure control: The double belt press laminating machine can accurately adjust the temperature and pressure, ensuring that the material is uniformly heated and pressurized throughout the entire process, avoiding the impact of non-uniformity on product quality. 2. High efficiency and high quality: Through the processing of double belt press laminating machines, the strength, stiffness, corrosion resistance and other properties of composite/laminated materials are greatly improved, while at the same time, the production efficiency is high and the product quality is stable. 3. Wide applicability: double belt press laminating machines can process various types of composite materials, such as carbon fiber, glass fiber, aramid fiber, as well as multiple resin systems (such as epoxy resin, phenolic resin, polyvinyl acetate resin, etc.), to meet the needs of different industrial fields. 4. Energy saving and environmental protection: Modern double belt press laminating machines adopt advanced heating systems (such as oil heating, steam heating, etc.), which can greatly reduce energy loss and reduce human operation errors and waste through automated control

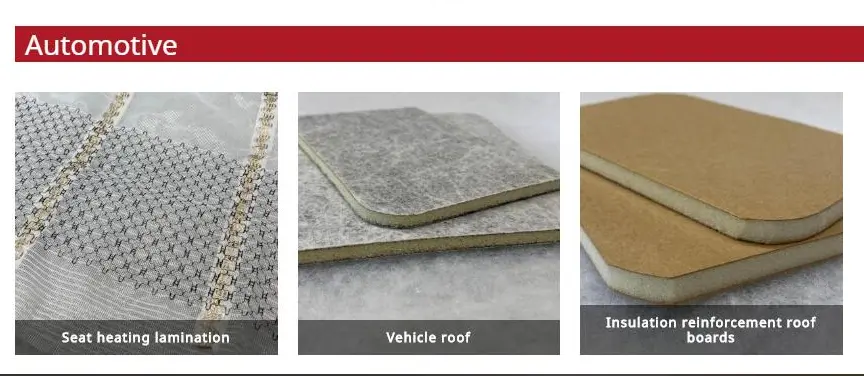

The new material continuous multi-layer composite automotive interior double belt press laminating machine has a wide range of application prospects in automotive interior manufacturing, including but not limited to the following aspects: 1. Automobile roof and sun visor: various materials (such as fabric, foam, film, etc.) can be compounded through a double belt press laminating machine to form an automobile roof and sun visor with excellent sound insulation, heat insulation, and aesthetics. 2. Door panels and seat covers: By using the hot pressing technology of a double belt press laminating machine, materials such as leather, fabric, and sponge can be tightly laminated to produce comfortable, durable, and aesthetically pleasing car door panels and seat covers. 3. New energy battery bottom guard plate: The development of new energy vehicles has put forward higher requirements for battery bottom guard plates. Double belt press laminating machines can composite/laminate high-strength and corrosion-resistant composite materials to meet the performance requirements of battery bottom guard plates. 4. Other interior components: Double belt press laminating machines can also be used to produce other components in automotive interiors, such as fenders, carpet coatings, interior panels, sound-absorbing elements, etc. These components play an important role in the comfort, safety, and aesthetics of automobiles.

What are the laminating machines used in car interior industry?

A laminating machine is a process of laminating two or more layers of materials together using adhesive or by flame or heat pressing. Thin films, cloth fibers, or glass cloth are often used, and commonly used automotive interior materials are composite materials based on leather, velvet, non-woven fabrics, etc. They are mainly used for the surface of car seats, armrest surfaces, instrument panel outer surfaces, steering wheels, interior walls of carriages, car ceilings, etc. Today we focus on the laminating machine application in car interior industry. When the interior materials of automobiles are manufactured and produced using a composite laminating machine, the two or more layers of materials are usually bonded/laminated together using adhesives or by heat pressing or flame.

There are generally four composite/laminating processes for automotive interior materials: 1. Through the Flame Laminating process, the composite/laminated product has good peel strength and no solvent residue. Due to the combustion composite/laminating process, it is inevitable that there will be residual smoke odor, so the composite/laminated product needs to undergo an additional deodorization process. Mainly targeting mid to high end car models. 2. Through the PU water based glue laminating process, the resulting product has poorer peel strength. Mainly targeting mid to low end car models. 3. Through the hot melt adhesive laminating process, the composite/laminated product has good peel strength, no solvent residue, and no smoke residue. The disadvantage is that the newly compounded product cannot have immediate fastness and needs to be left for more than 12 hours before use. Mainly targeting mid to high end car models. 4. Through double belt press laminating machine, both thin and thick materials, both materials in sheets and in rolls all can be laminated by this type of machine. The main disadvantage for this type of laminating machine is that the machine cost is high.

Hot Melt PUR Laminating Machine Advantages in Car Interior Industry:(1) Excellent environmental performance: The PUR hot melt adhesive used in the PUR hot melt adhesive laminating machine is 100% solid content, free of solvents and moisture. In the production process, there is no need to use open flames for processing like flame laminating machines, so there will be no harmful gas or dust emissions. This not only creates a fresh and healthy working environment for the production workshop, but also provides strong support for enterprises to fulfill their environmental responsibilities. Meanwhile, as there is no need for drying equipment, energy consumption is greatly reduced, which meets the requirements of sustainable development. (2) Significantly improved security: The PUR hot melt adhesive laminating machine eliminates the use of open flames and fundamentally eliminates the risk of fire accidents. During the operation of the equipment, parameters such as temperature and pressure can be precisely controlled to ensure the stability and reliability of the composite process. For automotive interior manufacturers, choosing PUR hot melt adhesive laminating machines adds a sturdy "safety lock" to their safety production, allowing them to focus on production in a safe environment. (3) Composite/Laminating effect is superior: In addition to its environmental and safety advantages, the PUR hot melt adhesive laminating machine also performs well in laminating effects. It can composite/laminate various automotive interior materials, such as car roof decorations, door pillars, car door panel fabric layers, etc. together. The special properties of PUR hot melt adhesive make the composite product have higher strength and better durability, which can effectively improve the overall quality and aesthetics of car interiors. Moreover, the environmental friendliness and weather resistance of PUR hot melt adhesive ensure the safety and stability of automotive interior materials during long-term use, providing consumers with a better product experience.

There are generally four composite/laminating processes for automotive interior materials: 1. Through the Flame Laminating process, the composite/laminated product has good peel strength and no solvent residue. Due to the combustion composite/laminating process, it is inevitable that there will be residual smoke odor, so the composite/laminated product needs to undergo an additional deodorization process. Mainly targeting mid to high end car models. 2. Through the PU water based glue laminating process, the resulting product has poorer peel strength. Mainly targeting mid to low end car models. 3. Through the hot melt adhesive laminating process, the composite/laminated product has good peel strength, no solvent residue, and no smoke residue. The disadvantage is that the newly compounded product cannot have immediate fastness and needs to be left for more than 12 hours before use. Mainly targeting mid to high end car models. 4. Through double belt press laminating machine, both thin and thick materials, both materials in sheets and in rolls all can be laminated by this type of machine. The main disadvantage for this type of laminating machine is that the machine cost is high.

Hot Melt PUR Laminating Machine Advantages in Car Interior Industry:(1) Excellent environmental performance: The PUR hot melt adhesive used in the PUR hot melt adhesive laminating machine is 100% solid content, free of solvents and moisture. In the production process, there is no need to use open flames for processing like flame laminating machines, so there will be no harmful gas or dust emissions. This not only creates a fresh and healthy working environment for the production workshop, but also provides strong support for enterprises to fulfill their environmental responsibilities. Meanwhile, as there is no need for drying equipment, energy consumption is greatly reduced, which meets the requirements of sustainable development. (2) Significantly improved security: The PUR hot melt adhesive laminating machine eliminates the use of open flames and fundamentally eliminates the risk of fire accidents. During the operation of the equipment, parameters such as temperature and pressure can be precisely controlled to ensure the stability and reliability of the composite process. For automotive interior manufacturers, choosing PUR hot melt adhesive laminating machines adds a sturdy "safety lock" to their safety production, allowing them to focus on production in a safe environment. (3) Composite/Laminating effect is superior: In addition to its environmental and safety advantages, the PUR hot melt adhesive laminating machine also performs well in laminating effects. It can composite/laminate various automotive interior materials, such as car roof decorations, door pillars, car door panel fabric layers, etc. together. The special properties of PUR hot melt adhesive make the composite product have higher strength and better durability, which can effectively improve the overall quality and aesthetics of car interiors. Moreover, the environmental friendliness and weather resistance of PUR hot melt adhesive ensure the safety and stability of automotive interior materials during long-term use, providing consumers with a better product experience.

Wechat: ANNIELV88

Wechat: ANNIELV88