How to operate hot melt laminating machine melter?

2025-06-05

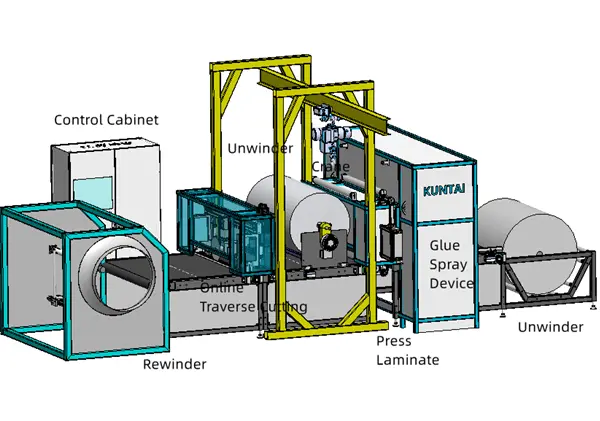

Because there are many types of hot melt adhesives for Hot Melt Laminating Machine, such as hot melt PUR glue, hot melt EVA glue, hot melt PSA glue and so on, there are also various types of hot melt glue melters. Here we will talk about how to operate hot melt PUR glue melter.

Generally, there are two specs of hot melt PUR melters: one is 55galon and the other is 5 galon. Most customers use 55galon melter for mass production of hot melt laminating machine.

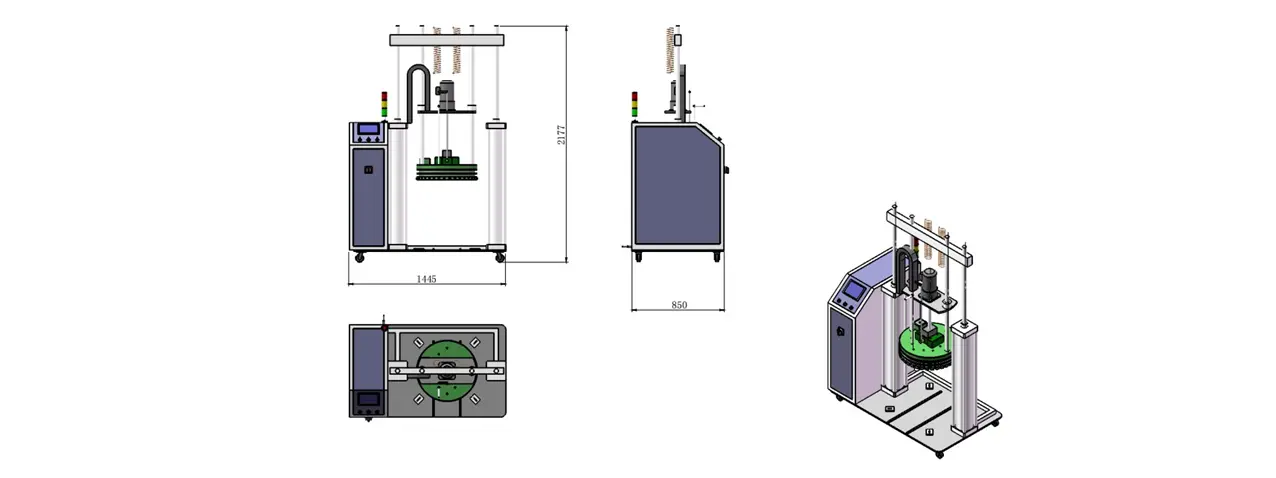

Hot melt laminating machine 55Galon PUR melter dimension:

When operating the hot melt laminating machine PUR melter, pls kindly note:

- When starting up, it is necessary to check whether the air source and power supply are normal (air pressure: about 0.5MP)

- The yellow indicator light indicates standby or heating status. The pressure plate lifting stop button can only be activated when the indicator light is green.

- For the first time using a new machine, if the power is turned on and the alarm light is red, it is an empty glue alarm. The electrical box must be opened and the rising solenoid valve must be manually pressed until the alarm is cleared

- When modifying the usage temperature, you need to enter the username and password.

- Enter the standby setting interface and turn Start Work on the "ON" pressure plate to start heating. Then, turn on theheating switch for the required tube gun on the temperature device interface.

- When pressing down on the pressure plate, high-temperature lubricating oil should be evenly applied to the sealing ring, and the exhaust valve should be opened. When there is glue overflowing from the exhaust valve, the exhaust valve should be immediately closed, and the glue overflowing from the exhaust valve should be wiped clean with a cloth, and high-temperature butter should be applied to the exhaust valve. After the temperature stabilizes, wait for 5-10 minutes before starting the motor. During the production process, the "Drop, Stop, Rise" button remains in the "Drop" state.

When the glue is used up, the indicator light will turn red and an empty glue alarm will appear.

- When changing the glue, fix the bottom four pressure plates onto the glue bucket, turn the "Drop, Stop, Rise" switch to "Rise" for about 5 seconds, then unscrew the 7-shaped solid rod on the pressure plate (glue will not flow out of this hole), replace the inflation rod and blow air into the glue bucket. When the pressure plate is about to detach from the gluebarrel, it is necessary to slow down the rising speed of the pressure plate and switch between Riseand Stop . After the pressure plate is completely detached, use a cloth to wipe off the remaining glue on the solid rod and tighten it on the pressure plate.

- At the end of production on the same day, the gun head must be sealed with high-temperature butter. If it is not used for a long time, it must be heated and discharged every other week. Alternatively, use a special cleaning agent to clean the entire rubber channel

- Please keep the exhaust hole, inflation hole, and inflation rod unobstructed.

Wechat: ANNIELV88

Wechat: ANNIELV88