2025-07-08

Set the oil heater and melter temparature as per your PUR glue spec. Normally for film lamination with fabric for mattress, our customers set oil heater as 100 celcius degree and melter as 90-95 celcius degree. While this is only a reference for hot melt PUR laminating machine, it must be set as per your specific type of PUR glue requirement. Pls refer to oil heater and melter operation manuals.

Using cleaning powder to clean the gluing roller of hot melt PUR laminating machine every time after work while the gluing roller is still hot. Some of our customers use local DMF cleaning chemical. When using DMF, pls take care and do not get it onto the silicone roller. Make sure glue does not stick into the gluing roller holes.

How to operate hot melt PUR laminating machine?

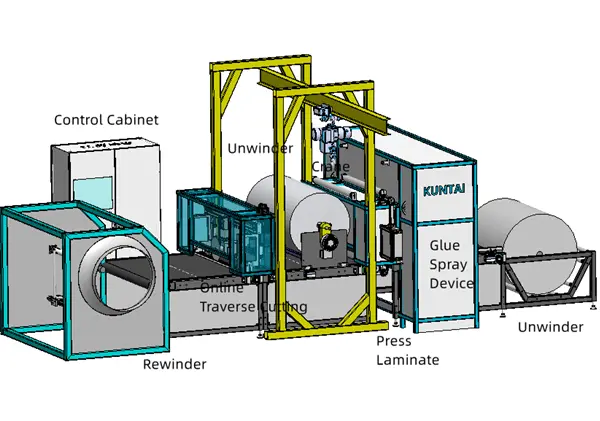

When you receive the hot melt PUR laminating machine, firstly, check all parts as per the machine drawing and spare parts list; secondly, layout the machine as per machine layout and your factory plan and productivity; thirdly, get qualified electrical technician get the machine connected; fourthly, get the machine trial tested without material loaded; fifthly, try the machine with materials loaded and hot melt PUR glue pumped. If needed, you can contact us for engineer onsite service which will cover all above procedures and get your people well trained in operating this type of laminatig machine. Everyday, except Chinese Spring Festival, Kuntai has engineers travelling overseas for installing and training of hot melt PUR laminating machine.

Pls do pay attention to safety during the installation, trial and operation of hot melt PUR laminating machine. Never put hands or body parts into any pinch points or pressing parts during machine running or operation. Pay attention to the cutters and keep safety. Any doubt, pls feel free to contact us first before taking any action to the hot melt PUR laminating machine.

To start normal running of the hot melt PUR laminating machne, get on power and check all parts, rollers and motors moving direction and position adjust direction. Make sure all movement of the hot melt PUR laminating machine in the correct direction. Check as per our provided machine running videos.

To start normal running of the hot melt PUR laminating machne, get on power and check all parts, rollers and motors moving direction and position adjust direction. Make sure all movement of the hot melt PUR laminating machine in the correct direction. Check as per our provided machine running videos.

One very important step in operating hot melt PUR laminating machine is to do zeroing, so that the machine glue quantity is well organized and precisely controlled.

Before using good quality fabrics or film for trial, you can use some waste fabric and film for trial test. Get them pass through the hot melt PUR laminating machine and pay attention to tension control and fabric spreader or opener pathways. Make adjustment to reach overall synchronization of the hot melt PUR laminating machine.

Wechat: ANNIELV88

Wechat: ANNIELV88