2025-08-03

4. Cotton and Silk Blends: Various fabrics made from blended yarns of cotton fibers and nylon fibers are widely used in military uniforms and workwear due to the excellent wear resistance and excellent elasticity recovery properties of nylon.

5. Anti-static Fabrics: Using yarn mixed with conductive fibers or fabric woven with conductive long filaments. Currently, the anti-static raw materials we use mainly include: organic conductive long filaments, short fibers and stainless steel fibers. Depending on the different uses of the clothing, different raw materials and ratios are selected.

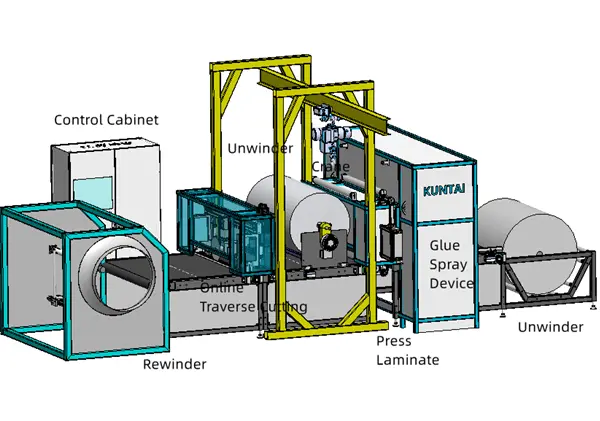

6. Composite Function Fabric: By using a special ratio of raw materials and specific production techniques like Laminating Machine, two or more new functions are combined onto the same fabric. In response to the various requirements for workwear in industries such as coal mining, petroleum, chemical engineering, the military, and firefighting, products that possess anti-static, moisture absorption, sweat discharge, and antibacterial and flame-retardant properties are developed. These products not only have anti-static functions but also have other properties such as moisture absorption and sweat discharge, and antibacterial and flame-retardant capabilities. They have met the needs of many mainstream customers both domestically and internationally, and have an extremely huge potential for future development.

What are functional fabrics?

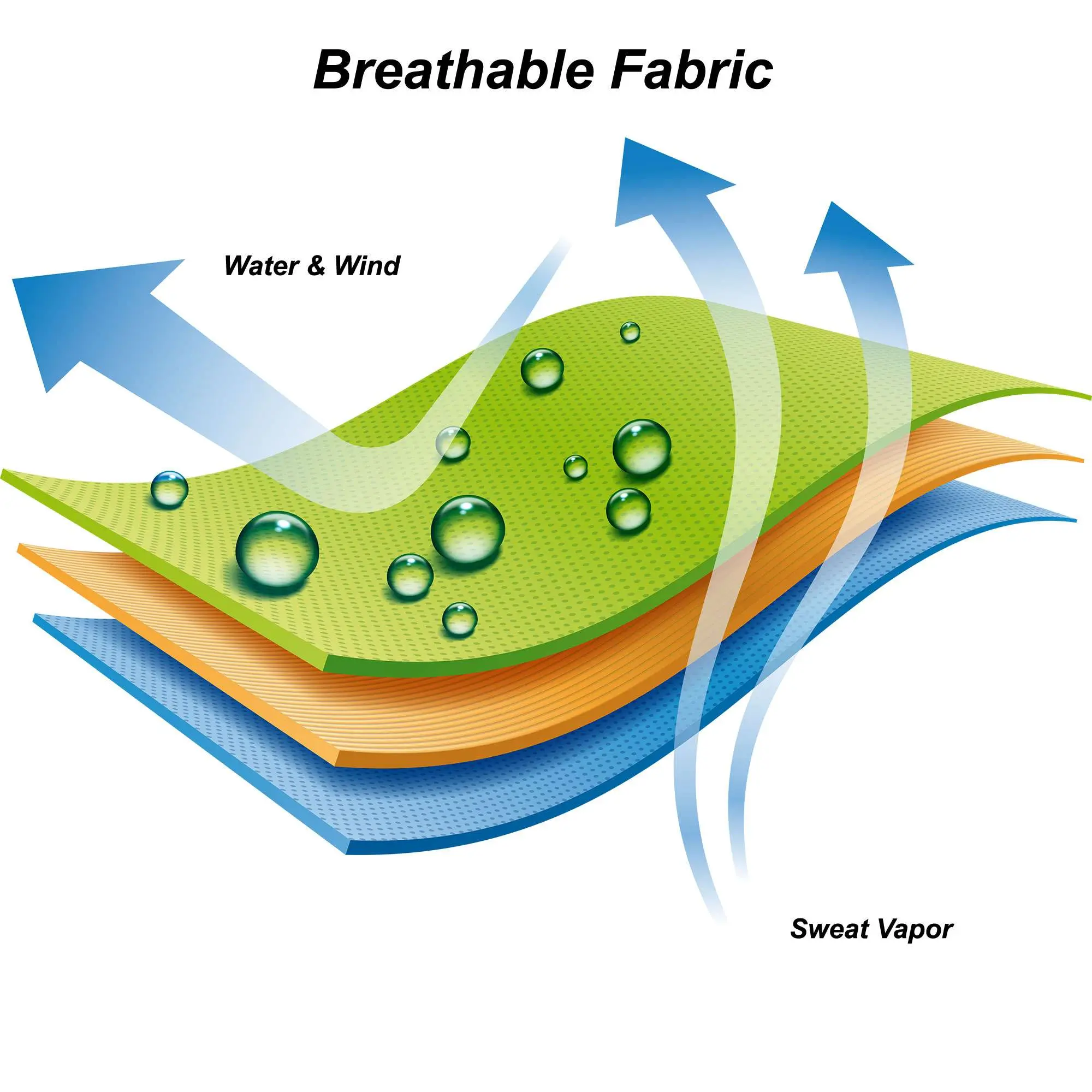

Functional fabrics refer to fabrics that have been modified in their properties, with functional materials added, or treated with various auxiliaries during the production process or post-treatment such as laminating machine, thereby endowing them with special functions and superior performance that are not possessed by ordinary clothing fabrics. Functional fabric functionality ☞Comfort features: high elasticity, memory effect, heat retention, windproof, waterproof, anti-wrinkle and stain-resistant, moisture absorption and sweat removal, etc. ☞ Health functions: Mold and bacteria prevention, dust mite prevention, virus resistance, mosquito prevention, negative ion health care, etc. ☞ Safety features: Wear-resistant, low-temperature resistant, UV-resistant, flame-retardant, anti-static, etc.

1. Moisture-wicking fabric: Mainly through physical methods, various special-shaped fibers such as cross-shaped, Y-shaped, T-shaped and honeycomb-shaped are produced. These fibers have a varying number of micro-grooves on their surface. By utilizing the core suction moisture-wicking structure of the grooves, moisture can be discharged from the body instantly. They are widely used in sports clothing, outdoor travel, casual wear, underwear, shirts and other fields.

2. Antibacterial Fabrics: Instead of the traditional method of adding antibacterial agents to the fabric, this technology involves melting antibacterial silver ion materials into the spinning melt, and then processing it through spinning to produce new antibacterial, sterilizing, and inhibitory functional silver ion fibers. The antibacterial rate is 99%.

3. Flame-retardant fabrics achieve permanent flame-retardant properties for fibers through polymerization, blending, copolymerization, composite spinning, and the incorporation of flame-retardants. The main types include: aramid, flame-retardant acrylic, flame-retardant viscose, flame-retardant polyester, and flame-retardant vinylon. They are widely used in industries such as the military, firefighting, petroleum, power, natural gas, chemical, aviation, and shipping. They are also used to make general clothing, especially children's clothing, pajamas, carpets, bedding, etc.

1. Moisture-wicking fabric: Mainly through physical methods, various special-shaped fibers such as cross-shaped, Y-shaped, T-shaped and honeycomb-shaped are produced. These fibers have a varying number of micro-grooves on their surface. By utilizing the core suction moisture-wicking structure of the grooves, moisture can be discharged from the body instantly. They are widely used in sports clothing, outdoor travel, casual wear, underwear, shirts and other fields.

2. Antibacterial Fabrics: Instead of the traditional method of adding antibacterial agents to the fabric, this technology involves melting antibacterial silver ion materials into the spinning melt, and then processing it through spinning to produce new antibacterial, sterilizing, and inhibitory functional silver ion fibers. The antibacterial rate is 99%.

3. Flame-retardant fabrics achieve permanent flame-retardant properties for fibers through polymerization, blending, copolymerization, composite spinning, and the incorporation of flame-retardants. The main types include: aramid, flame-retardant acrylic, flame-retardant viscose, flame-retardant polyester, and flame-retardant vinylon. They are widely used in industries such as the military, firefighting, petroleum, power, natural gas, chemical, aviation, and shipping. They are also used to make general clothing, especially children's clothing, pajamas, carpets, bedding, etc.

Wechat: ANNIELV88

Wechat: ANNIELV88