2025-08-07

Laminated Fabric Adhesive Laminating Production principle: The core components of the Laminating Machine are the gluing device and the lamianting device. When the surface cloth (film) passes through the gluing device, the glue in the carving roller's glue hole is forced to transfer to the surface cloth (film) by the gluing pressure roller, and then pressed by the composite device to obtain the initial adhesion strength.

Double Belt Press Laminating Production principle: The raw materials will be fed onto the double belt press laminating machine after adding glue or powder or attaching hot melt film and then heating, pressing and cooling. If needed, chiller can be used.

Laminated Fabric Maintenance treatment The duration of maintenance treatment has a significant impact on the firmness of fabric bonding/laminating and the degree of adhesive fusion. The maintenance treatment workshop is fully enclosed, and a certain temperature and humidity are maintained indoors to allow the adhesive to naturally fuse. If the temperature is increased in order to complete the process quickly, the yarn of the fabric is prone to needle breakage during the sewing process, the hand feel becomes hard, and there will be a rustling sound when rubbed against each other, indicating that the adhesive has solidified on the fabric and made the yarn of the fabric harder.

What are composite fabrics?

Composite fabric is a new type of material made by bonding one or more layers of textile materials, non-woven materials, and other functional materials together by laminating machine. Suitable for making sofas, clothing and other textiles, it is one of the indispensable fabrics for people's home life. Classification of composite fabrics 1. Laminating of woven fabric and knitted fabric 2. Knitted fabrics and knitted fabric laminating 3. Woven fabric and woven fabric laminating 4. Fabric and film laminating 5. Fabric and paper laminating

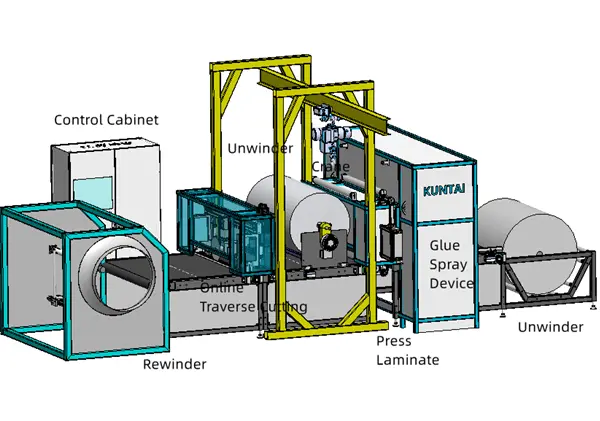

Popular composite fabric techniques internationally 1. Hot melt adhesive powder dot coating laminating machine: To laminate fabrics using hot melt powder by way of scatter coating and powder dot transfer coating. Normally used in interlining, suit etc. 2. Hot melt adhesive dot transfer laminating machine: To laminate fabrics using hot melt adhesive, such as hot melt EVA glue, hot melt PUR glue, hot melt PSA glue and so on. This is very popular currently, especially hot melt PUR laminating machine, widely used in garment industry, sofa fabric, carpet, blanket, mattress protector, blackout curtain, car interior, etc. 3. Hot melt adhesive coating laminating machine: To laminate fabrics using way of roller coating or slot die coating, etc. 4. Hot melt film laminating machine: To laminate fabrics using hot melt film adhesive or web adhesive. 5. Spray coating laminating machine: To laminate fabric using spray type laminating. Spray water based glue or solvent based glue or hot melt glue, etc. Normally used in scouring pad lamination or thick foam lamination or filter materials industry. 6. Water based glue laminating machine: To laminate fabrics using water based glue, normally used in shoes industry or car interior industry, etc 7. Solvent based glue laminating machine: To laminate fabric using solvent based glue, for strong bonding, while this type of glue has strong smell during laminating process. 8. Flame Laminating machine: To laminate fabrics using fire retardant foam. Widely used in car interior indusry, etc 9. Double belt press laminating machine: To laminate either sheets or rolls materials by heating and pressing.

Popular composite fabric techniques internationally 1. Hot melt adhesive powder dot coating laminating machine: To laminate fabrics using hot melt powder by way of scatter coating and powder dot transfer coating. Normally used in interlining, suit etc. 2. Hot melt adhesive dot transfer laminating machine: To laminate fabrics using hot melt adhesive, such as hot melt EVA glue, hot melt PUR glue, hot melt PSA glue and so on. This is very popular currently, especially hot melt PUR laminating machine, widely used in garment industry, sofa fabric, carpet, blanket, mattress protector, blackout curtain, car interior, etc. 3. Hot melt adhesive coating laminating machine: To laminate fabrics using way of roller coating or slot die coating, etc. 4. Hot melt film laminating machine: To laminate fabrics using hot melt film adhesive or web adhesive. 5. Spray coating laminating machine: To laminate fabric using spray type laminating. Spray water based glue or solvent based glue or hot melt glue, etc. Normally used in scouring pad lamination or thick foam lamination or filter materials industry. 6. Water based glue laminating machine: To laminate fabrics using water based glue, normally used in shoes industry or car interior industry, etc 7. Solvent based glue laminating machine: To laminate fabric using solvent based glue, for strong bonding, while this type of glue has strong smell during laminating process. 8. Flame Laminating machine: To laminate fabrics using fire retardant foam. Widely used in car interior indusry, etc 9. Double belt press laminating machine: To laminate either sheets or rolls materials by heating and pressing.

Wechat: ANNIELV88

Wechat: ANNIELV88