product description

Kuntai Group

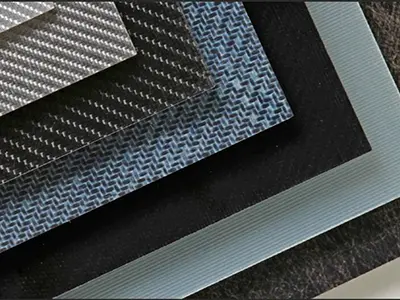

Continuous Fiber Reinforced Thermoplastic Composite (CFRTP) is a high-performance composite material that uses continuous fibers as reinforcement material and thermoplastic resin as matrix. Its main features include:

Excellent mechanical properties: Compared with traditional thermoplastic composite materials, CFRTP performs better in strength and rigidity.

Lightweight and high-strength: It has good impact resistance and short molding cycle, suitable for various applications.

Wide application: Widely used in aerospace, automotive, rail transit and other fields.

Recyclability: Waste can be recycled and reused, meeting the requirements of sustainable development.

Manufacturing process: Adopting thermoplastic resin melt impregnation process, it has high strength and toughness.

These characteristics make CFRTP highly regarded in the composite materials industry and a hot research topic.

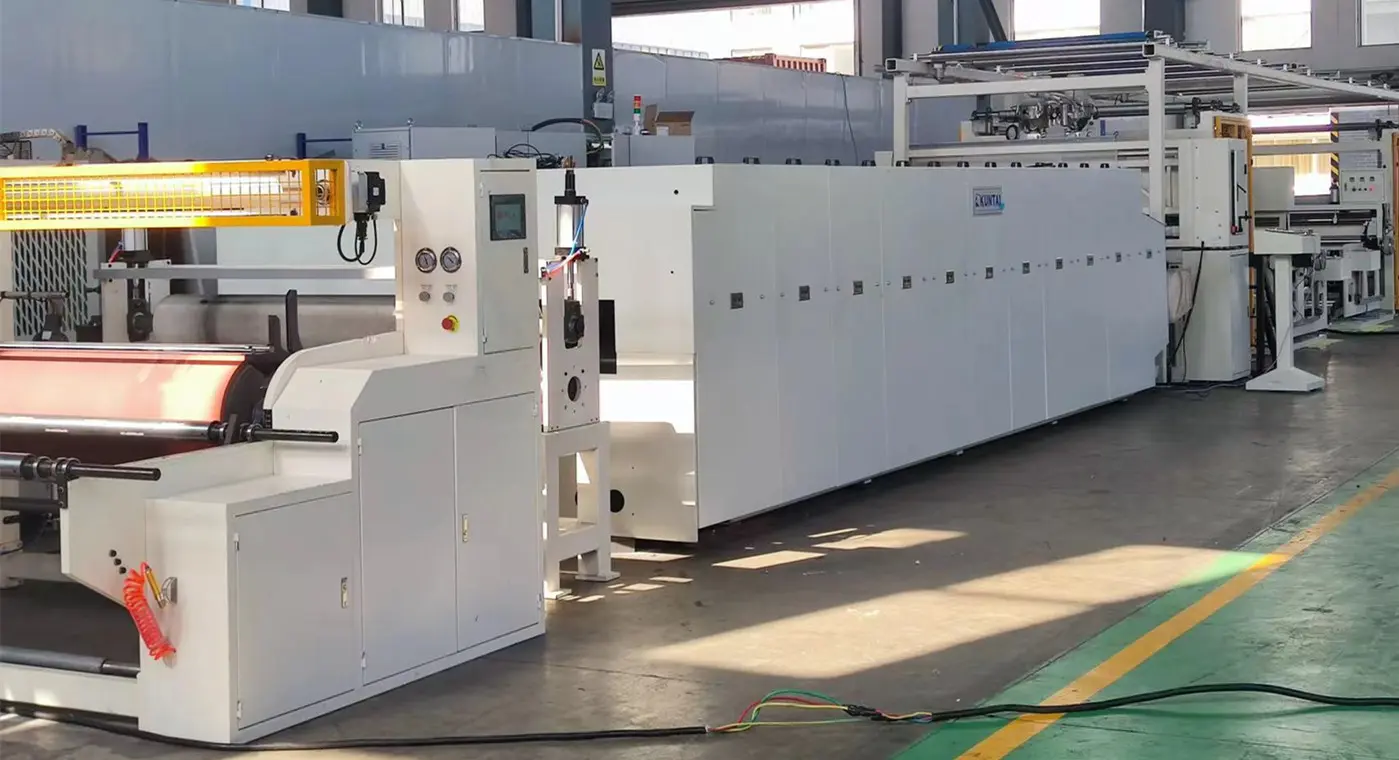

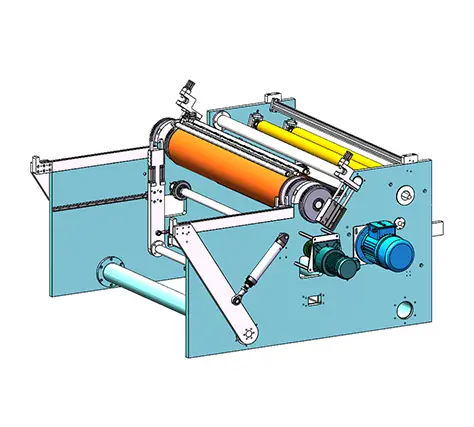

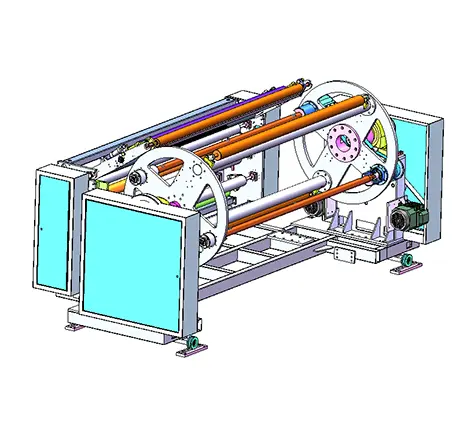

Because under heating Continuous Fiber Reinforced Thermoplastic will melt and bond, more and more people choose to use double belt press machine to laminate it for continuous mass production.

Double belt press for continuous fiber-reinforced thermoplastic have been widely used in various fields such as the automotive industry, aerospace, military, electronics, etc. due to their lightweight, high stiffness, and high toughness characteristics.

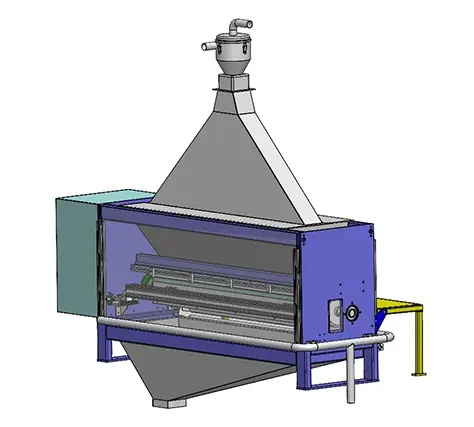

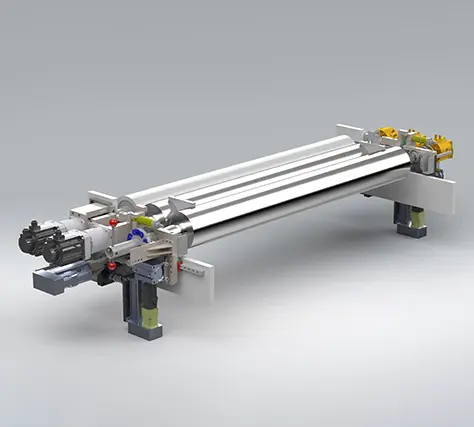

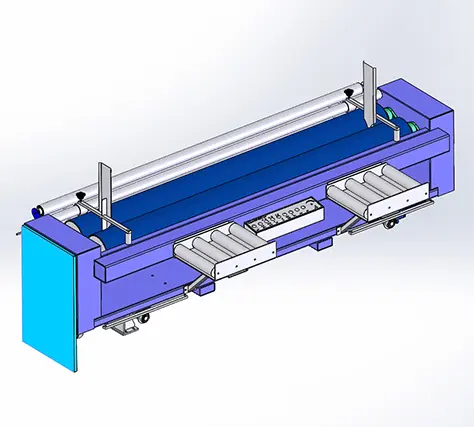

In our double belt press laminating machine, there is cooling section which greatly improves the final bonding laminating strength for Continuous fiber-reinforced thermoplastic composites.

Applicable adhesives

Kuntai Group

Hot melt adhesive film, hot melt EVA powder, thermoplastic materials, etc.

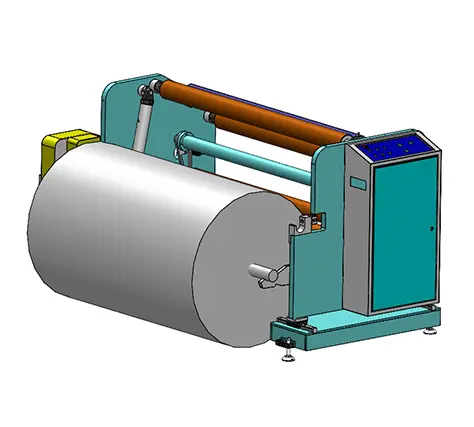

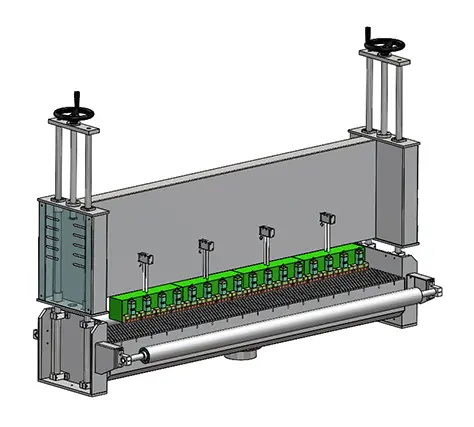

AccessoriesOption

01020304050607080910

Machine Features

Kuntai Group

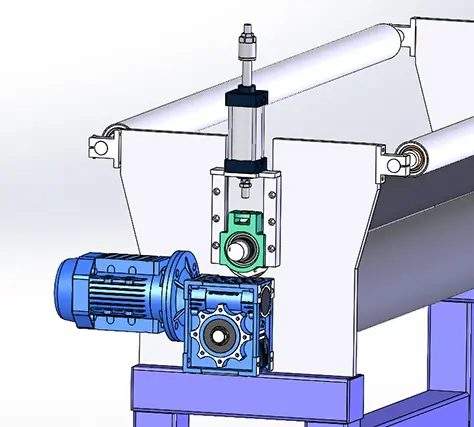

● Temperature can be upto 230°C and you can set different temperatures in all zones. Arrangement of heating elements and edge zone division of the entire heating system can be customized as per each specific application, minimizing variations and defect in the final laminated product.

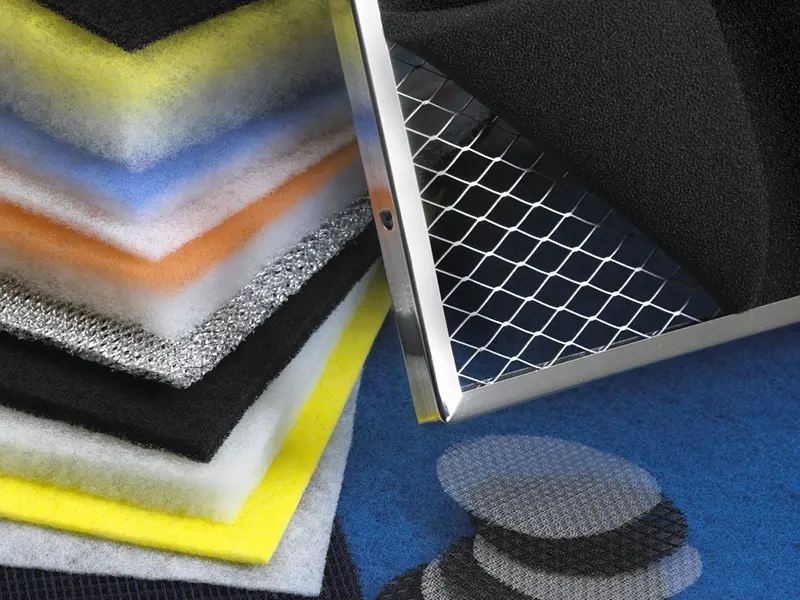

● Suitable for rolls and sheets and panels with thickness upto 150mm.

● Multilayers of materials can be laminated in one time.

● For bonding, heat setting, alignment and/or surface consolidation

● Working width upto 3000mm.

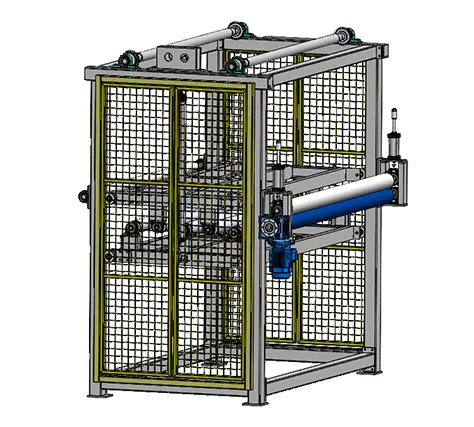

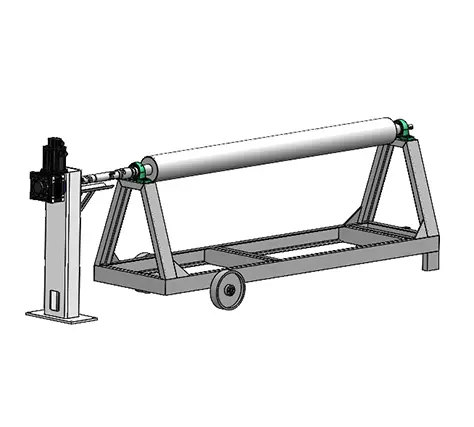

● Machine structure customizable. Different materials loading devices, tension control methods, online fixed length cutting device and other devices are available for choice.

● Raw materials saving, precise position control, high productivity, stable structure

● Convenient, highly efficient, labor saving

● Higher automation

Technical Parameters (Customizable)

Kuntai Group

| Width | 1100mm, 1300mm, 1500mm, 1600mm,1800mm, 2000mm, according to customers' requirement |

| Machine Speed | 0.5 to 30m/min |

| Height Adjustment | 0 to 150mm |

| Heating Zone | 2500mm, 3000mm, according to customers' requirement |

| Cooling Zone | 1500mm, 2000mm, according to customers' requirement |

| Control Zones | 18 |

| Machine Heating Power | 120-380kw, Customizable |

| Voltage | 220v, 380v, Customizable |

| Control system | Touch screen, PLC, servo motor |

| Varieties | a. Integrated heating and cooling zone b. Only with heating zone c. Only with cooling zone d. One set of pressing rollers or two sets |

Application

Kuntai Group

The Double Belt Press For Continuous Fiber Reinforced Thermoplastic is widely used in the high and new tech materials industries:

✓ Automotive lightweight

✓ Sports, leisure, and 3C peripherals: Continuous fiber-reinforced thermoplastic composite materials are widely used in high-end sports shoes, helmets, suitcases, sports equipment accessories, phone cases, and other fields due to their high impact resistance and fast forming characteristics

✓ Application in aerospace and military fields: High performance carbon fiber, aramid fiber, and glass fiber are generally used as reinforcing materials in the aerospace industry

✓ Continuous fiber-reinforced PEEK not only has the characteristics of thermoplastic materials, but also has excellent flame retardant properties such as good self extinguishing, low smoke, and non-toxic combustion products. Due to its X-ray transparency, good biocompatibility, strong antibacterial properties, long-term implantation in the human body, and elastic modulus similar to bones, it is widely used in the medical field. Currently, TenCate, Ticona, and others are available to provide this product.

✓ High speed rail, ships, fan blades, high-pressure gas cylinders, etc

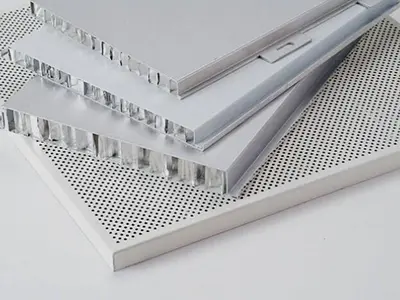

✓ Construction Industry: Honeycomb panel materials

Packaging And Shipping

Kuntai Group

Double Belt Press For Continuous Fiber Reinforced Thermoplastic Inner Package: Protective Film, etc .

Double Belt Press For Continuous Fiber Reinforced Thermoplastic Outside Package: Export Container

◆ Machines well packed with protective film and loaded with export container;

◆ One-Year-Period spare parts;

◆ Tool kit

0102030405060708

01

Jiangsu Kuntai Machinery Co., Ltd

Phone/Whatsapp: +86 15862082187

Address: Zhengang Industrial Park, Yancheng City, Jiangsu Province, China

Wechat: ANNIELV88

Wechat: ANNIELV88