In the fast-evolving world of manufacturing, the efficient use of a PVC Coating Laminating Line is crucial for producing high-quality products. This technology has transformed many industries by offering durability, resistance, and aesthetic appeal. However, many users encounter challenges while operating this equipment.

Understanding how to maximize the potential of a PVC Coating Laminating Line requires insight and hands-on experience. Consistent training and adaptation are key. Whether you are in textiles, automotive, or other sectors, recognizing common pitfalls can lead to improvements. Mistakes happen, such as improper temperature settings or inadequate surface preparation. These will impact the end result.

Continuous evaluation of the process can yield insights into better practices. Engaging skilled operators who can troubleshoot issues is essential. Identifying flaws in the production line not only saves costs but also enhances overall efficiency. The journey toward mastering the PVC Coating Laminating Line remains one of trial and learning.

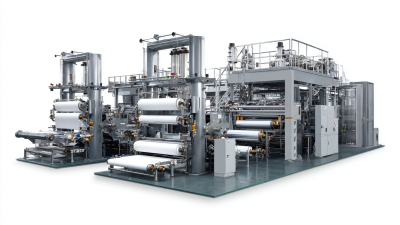

PVC coating laminating lines have become crucial in various industries. Understanding how they function can enhance productivity significantly. This process involves coating materials with PVC to improve durability and aesthetics. Recent studies indicate that efficient lines can increase production rates by up to 30%. However, this potential is only realized with a proper setup.

Maintenance is vital. Regular checks of equipment ensure optimal performance. Data from industry reports suggest that neglecting maintenance can lead to a 15% decrease in efficiency. The lines should be calibrated frequently to handle different materials effectively. Proper calibration ensures consistent thickness and quality, which are critical factors in the end product’s performance.

Training operators is another area that requires attention. Skilled workers can identify early signs of malfunction, thus preventing costly downtime. Surveys show that 40% of operators feel inadequately trained. This gap can lead to errors that impact production quality. Investing in thorough training can mitigate these risks, ensuring a smooth operation that maximizes the effectiveness of PVC coating laminating lines.

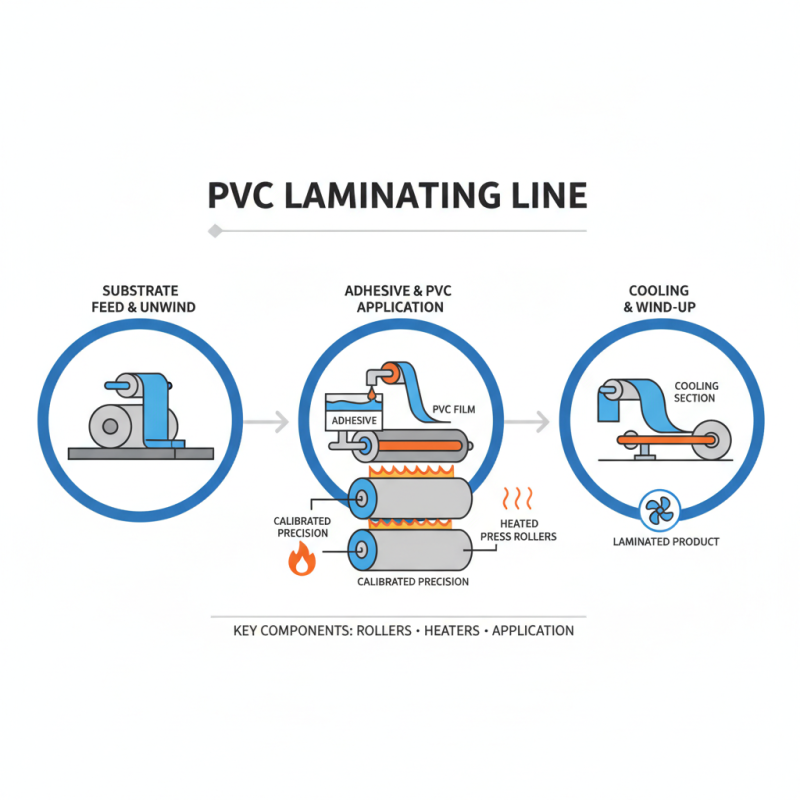

A PVC coating laminating line is composed of several key components. The core machinery includes rollers, heaters, and an application station. Each part serves a purpose in the lamination process. Rollers press the PVC onto the substrate. They must be precisely calibrated. Any misalignment can lead to uneven coatings.

Heating elements play a critical role too. They ensure the PVC adheres well. If the temperature fluctuates, the coating can become uneven. This affects the final product quality. Operators need to monitor temperatures closely. Surveys and adjustments often go hand-in-hand.

The application station can be complex. It dispenses a controlled amount of PVC onto the substrate. Too much or too little can ruin the coating's integrity. User experience is essential here. Training personnel effectively can mitigate common issues. Regular maintenance of equipment can prevent breakdowns. Yet, problems may still arise. Reflecting on challenges helps refine processes.

Setting up a PVC coating laminating line can be a complex process. It requires careful planning and execution. Begin by assessing your workspace. Make sure you have enough room for all equipment. Consider the flow of materials. A well-organized layout saves time.

Next, focus on selecting the right equipment. Not all laminating machines are created equally. Look for features that suit your production needs. Some machines may require additional training. Ensure your team can operate them properly. This minimizes errors during production.

During setup, pay attention to safety protocols. Proper ventilation is crucial. Working with PVC can release harmful fumes. Regular maintenance checks are also essential. Neglected machines can lead to inefficiencies and delays. Document your processes to identify areas for improvement later on. Reflect on what works and what doesn’t for future projects.

Operating a PVC coating laminating line effectively requires attention to detail and a proactive approach. The environment plays a crucial role. Ensure that the area is clean and organized. Dust and debris can affect the quality of the final product. Regularly check the equipment for any signs of wear and tear. Overlooking small issues can lead to larger complications later on.

Training staff properly is essential. Workers should understand the entire process, from setup to maintenance. They should feel confident in troubleshooting minor problems. However, even with training, mistakes may happen. Learning from these mishaps is key. Embrace feedback to improve workflows.

Monitoring temperature and humidity levels is vital for optimal output. Both elements influence how the adhesive interacts with the PVC. Inconsistent readings can lead to poor bonding. Regular calibration of machinery helps to maintain optimal performance. Make it a routine to collect data and assess for patterns. Stagnation can hinder progress, so remain adaptable to changes in the process.

| Best Practice | Description | Frequency | Responsibility |

|---|---|---|---|

| Regular Maintenance | Perform routine checks on machinery to ensure optimal functioning. | Monthly | Maintenance Team |

| Operator Training | Provide comprehensive training for operators to enhance skill levels. | Bi-annually | HR Department |

| Material Quality Check | Inspect raw materials before use to prevent defects in the final product. | Every Batch | Quality Control Team |

| End-of-Shift Reporting | Complete reports on production and highlight any issues for the next shift. | Daily | Operators |

| Safety Protocols | Adhere to safety protocols to minimize workplace accidents. | Continuous | All Employees |

PVC coating laminating is essential in various industries, yet it comes with notable challenges. Inefficient pre-treatment of surfaces can lead to poor adhesion. Reports indicate that improper surface preparation can reduce adhesion strength by up to 50%. This loss translates into product weaknesses, increasing the risk of warranty claims.

Calibrating temperature precisely is another recurring issue. Too high, and you may end up with bubbles; too low, and the coating may not properly bond. A study revealed that maintaining optimal temperatures within plus or minus 5 degrees Celsius significantly enhances product consistency. Many operators often overlook this aspect, assuming a one-size-fits-all approach works.

Lastly, operator training is frequently inadequate. A skilled operator can spot potential issues quickly, while an untrained one may miss critical defects. Research has shown that companies investing in operator training see a decrease in production errors by nearly 30%. Improving skill sets can make a remarkable difference in the final output quality. The journey to mastering PVC coating laminating is marked by these common obstacles. Addressing them requires ongoing evaluation and adjustment.