In the realm of modern fabrication and cutting processes, the Swing Arm Cutting Machine stands out as an indispensable tool for achieving precision and efficiency. This innovative equipment is designed to enhance the cutting experience, providing users with the ability to execute precise cuts consistently across a variety of materials. The unique swing arm mechanism not only improves maneuverability but also ensures greater accuracy, making it ideal for industries where detail is paramount. As manufacturers and artisans strive for excellence in their projects, the Swing Arm Cutting Machine emerges as a best-in-class solution that combines technology and functionality. Moreover, its versatility allows for seamless integration into diverse workflows, catering to both large-scale operations and smaller workshops. In this exploration, we will delve into the numerous features and advantages that make the Swing Arm Cutting Machine essential for precision cutting, highlighting its importance in achieving superior results across different applications.

In the realm of modern fabrication and cutting processes, the Swing Arm Cutting Machine stands out as an indispensable tool for achieving precision and efficiency. This innovative equipment is designed to enhance the cutting experience, providing users with the ability to execute precise cuts consistently across a variety of materials. The unique swing arm mechanism not only improves maneuverability but also ensures greater accuracy, making it ideal for industries where detail is paramount. As manufacturers and artisans strive for excellence in their projects, the Swing Arm Cutting Machine emerges as a best-in-class solution that combines technology and functionality. Moreover, its versatility allows for seamless integration into diverse workflows, catering to both large-scale operations and smaller workshops. In this exploration, we will delve into the numerous features and advantages that make the Swing Arm Cutting Machine essential for precision cutting, highlighting its importance in achieving superior results across different applications.

In today's competitive manufacturing landscape, precision is paramount. According to a report by the Georgetown University Center on Education and the Workforce, precision manufacturing jobs are projected to grow by 9% over the next decade, underscoring a crucial demand for technology that supports exacting standards. The use of swing arm cutting machines, known for their ability to deliver intricate cuts with tolerances as tight as ±0.005 inches, illustrates the significance of precision in modern manufacturing processes.

Moreover, a study by the National Institute of Standards and Technology (NIST) reveals that a mere 0.1% increase in accuracy can lead to up to 20% cost savings in materials and time for manufacturing operations. This illustrates that investing in precision technologies such as swing arm cutting machines not only enhances product quality but also significantly reduces waste, aligning with sustainability goals in the industry. As businesses strive for efficiency and excellence, the integration of precision cutting tools will be essential to meet the evolving demands of the global market.

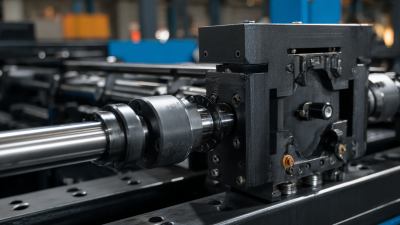

Swing arm cutting machines have become essential tools in industries requiring precision and accuracy. One of the key features that enhance their performance is the adjustable swing arm mechanism. This design allows for optimal control and maneuverability, ensuring that every cut is executed exactly where intended. The ability to tilt and rotate the cutting surface means that intricate designs can be tackled with confidence.

Another standout feature is the built-in digital measurement systems that provide real-time feedback. These systems allow operators to make quick adjustments, reducing the likelihood of errors during the cutting process. Additionally, many models come equipped with robust safety features, protecting both the machine and the user while maintaining high levels of accuracy.

**Tips:** When using a swing arm cutting machine, always verify the calibration before starting a project. Regular maintenance is essential to ensure precision remains consistent. Lastly, familiarizing yourself with the machine's unique attributes can significantly enhance your cutting efficiency and accuracy.

The advancements in swing arm technology have significantly transformed the landscape of precision cutting, particularly in industries such as textiles and manufacturing. According to a report by the International Journal of Advanced Manufacturing Technology, swing arm cutting machines can improve cutting accuracy by up to 20% when compared to traditional methods. This increase in precision is largely due to the machine's inherent design, which allows for more stable operation and reduced vibration during the cutting process.

Moreover, the consistency achieved through swing arm technology is remarkable. A study published by the Society of Manufacturing Engineers highlights that the use of swing arm cuttings can lead to a reduction in material waste by approximately 15%. This is crucial for manufacturers looking to optimize production efficiency while maintaining high-quality standards. The reliability of swing arm machines means less variability in output, which helps businesses meet the rigorous demands of modern production schedules while ensuring that every cut is executed with precision and uniformity.

| Feature | Description | Benefits |

|---|---|---|

| Swing Arm Design | A unique pivot mechanism that allows for greater flexibility in movement. | Enhances agility and ease of operation, reducing operator fatigue. |

| Precision Cutting | Cuts are made with high accuracy due to advanced alignment features. | Improves product quality and consistency in output. |

| Material Versatility | Can cut a variety of materials including wood, metal, and plastic. | Increases the range of applications and marketability. |

| User-Friendly Interface | Intuitive controls and displays for ease of use. | Reduces training time and increases operational efficiency. |

| Safety Features | Includes guards and emergency stops to protect operators. | Minimizes workplace accidents, ensuring a safer working environment. |

In the realm of precision cutting, the compatibility of materials and the cutting machine plays a pivotal role. A swing arm cutting machine, renowned for its versatility, can achieve optimal results only when paired with materials that cater to its operational design. Research indicates that about 70% of cutting inaccuracies stem from improper material selection, highlighting how critical this relationship is in the manufacturing process. For instance, a cutting machine designed for softer materials may struggle with denser composites, leading to poor finishes and increased wear on blades.

Furthermore, specific material properties, such as thickness and elasticity, can significantly affect the outcome of the cuts. According to a report by the National Institute of Standards and Technology, precision cutting applications have seen a 40% improvement in efficiency when utilizing machines adequately matched to the materials being cut. This emphasizes the necessity for manufacturers to invest in machinery that aligns with their operational needs, not just to enhance productivity but also to maintain quality standards throughout the production cycle. Understanding the synergy between material characteristics and cutting technology is fundamental to achieving the desired precision and efficiency in any cutting operation.

Investing in high-quality cutting machinery, specifically swing arm cutting machines, offers significant economic benefits for businesses focused on precision cutting. These machines are designed to enhance cutting accuracy, reducing material waste and improving overall efficiency in production. With their advanced technology, they allow for precise cuts that can significantly lower the cost per unit, leading to higher profit margins. This precision minimizes the need for rework or material wastage, which can be costly and time-consuming.

Investing in high-quality cutting machinery, specifically swing arm cutting machines, offers significant economic benefits for businesses focused on precision cutting. These machines are designed to enhance cutting accuracy, reducing material waste and improving overall efficiency in production. With their advanced technology, they allow for precise cuts that can significantly lower the cost per unit, leading to higher profit margins. This precision minimizes the need for rework or material wastage, which can be costly and time-consuming.

Moreover, high-quality cutting machinery often comes with longer lifespans and lower maintenance costs compared to their lower-quality counterparts. By choosing to invest in robust and reliable equipment, businesses can avoid frequent repairs and replacements, ensuring smoother operations and reducing downtime. This investment in machinery not only optimizes production but also contributes to better customer satisfaction through consistent quality, ultimately solidifying a company's reputation in the market.

In today's competitive landscape, the economic advantages of deploying efficient cutting machines cannot be overstated; they play a crucial role in driving profitability and sustaining business growth.