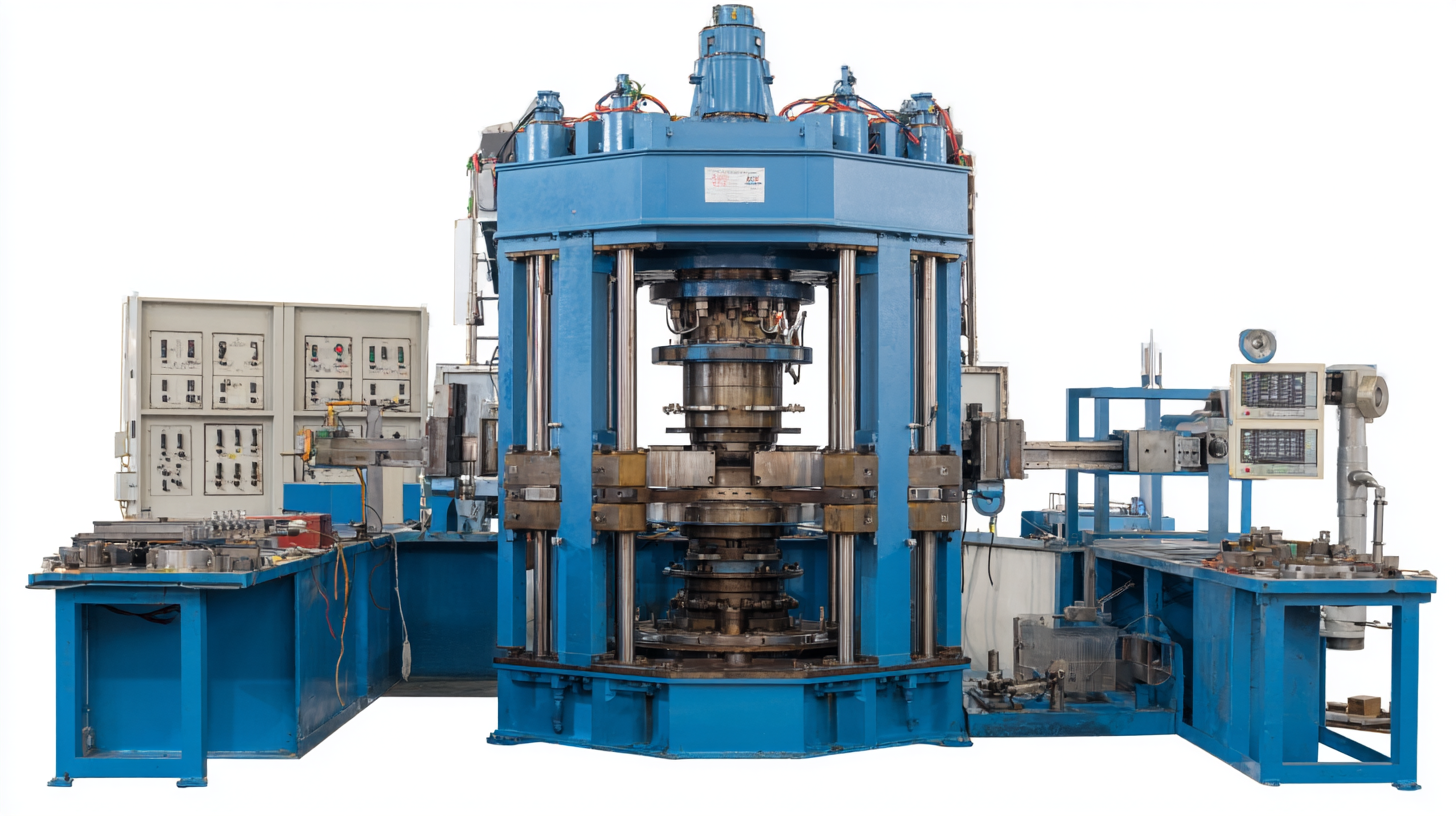

In today's fast-paced manufacturing landscape, the quest for efficiency and innovation remains paramount. One of the transformative technologies reshaping the industry is the Hydraulic Cutting Press. This powerful machine not only enhances precision in cutting but also streamlines production processes, allowing manufacturers to meet the growing demands of modern markets. As industries evolve, understanding the integration of hydraulic cutting technology and its impact on manufacturing efficiency becomes crucial. This article delves into the latest insights and practical tips for harnessing the full potential of Hydraulic Cutting Press systems, exploring how they can revolutionize operations and foster competitive advantages in a rapidly changing environment. Join us as we uncover the pivotal role of this technology in driving productivity and innovation within the manufacturing sector.

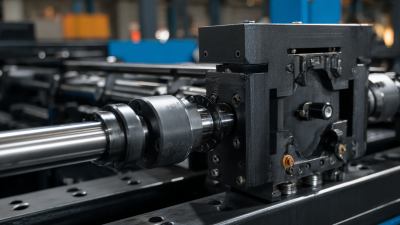

Hydraulic cutting press technology has made significant strides in recent years, providing manufacturers with enhanced efficiency and precision. With the integration of advanced hydraulic systems, these presses are now capable of executing complex cuts with minimal lead times. This progress not only increases production rates but also reduces material waste, thereby optimizing the overall manufacturing process. Additionally, the introduction of smart technology allows for real-time monitoring and adjustments, ensuring consistent quality in every batch.

For manufacturers looking to leverage hydraulic cutting press technology, here are a few essential tips:

Hydraulic cutting presses are transforming the manufacturing landscape by offering numerous benefits that enhance operational efficiency. One of the key advantages is their ability to deliver precise cuts with minimal waste, enabling manufacturers to optimize material usage. This efficiency not only reduces production costs but also minimizes environmental impact, aligning with modern sustainability goals. The consistent pressure exerted by hydraulic systems ensures uniformity in product quality, which is critical for industries demanding high precision in their components.

Moreover, hydraulic cutting presses facilitate faster production cycles. Their rapid operational capacity means manufacturers can increase output without compromising on quality. This is particularly beneficial in high-demand sectors where time-to-market is crucial. The versatility of hydraulic cutting presses allows them to handle a diverse range of materials, from metals to composites, making them indispensable in varied applications. By integrating advanced hydraulic technology, manufacturers can remain competitive, streamline operations, and adapt to changing market needs, all while enjoying the benefits of enhanced productivity and quality assurance.

This bar chart illustrates the key benefits of hydraulic cutting presses used in modern manufacturing, highlighting enhancements in efficiency, precision, and operational cost savings.

The shift towards hydraulic cutting presses is transforming manufacturing efficiency by offering advantages that traditional cutting methods cannot match. A recent industry report indicates that hydraulic presses can achieve cutting speeds up to 30% faster when compared to mechanical or manual cutting processes. This increased speed translates to higher production rates, allowing manufacturers to respond swiftly to market demands. Moreover, hydraulic cutting presses provide enhanced precision, reducing material wastage by approximately 15%, resulting in significant cost savings.

The shift towards hydraulic cutting presses is transforming manufacturing efficiency by offering advantages that traditional cutting methods cannot match. A recent industry report indicates that hydraulic presses can achieve cutting speeds up to 30% faster when compared to mechanical or manual cutting processes. This increased speed translates to higher production rates, allowing manufacturers to respond swiftly to market demands. Moreover, hydraulic cutting presses provide enhanced precision, reducing material wastage by approximately 15%, resulting in significant cost savings.

Tips: When considering the transition to hydraulic cutting technology, evaluate your current production volume and assess how much time you might save. Investing in hydraulic systems can yield a quick return on investment through improved efficiency and lower material costs.

In contrast, traditional cutting methods often involve more complex setups and slower processing times, which can hinder productivity. A comparative analysis reveals that manufacturers utilizing hydraulic cutting presses can experience fewer operational interruptions due to their streamlined design and automated features. This allows for a more consistent workflow and reduced labor costs, positioning companies for greater competitiveness in a fast-evolving industry landscape.

Tips: It's essential to conduct a thorough cost-benefit analysis before switching technologies. Take into account not just initial costs but also long-term savings and productivity enhancements that hydraulic cutting presses could offer.

The implementation of hydraulic cutting press technology in manufacturing has proven transformative, particularly when examining various industry case studies. For instance, the automotive sector has reported a notable increase in production efficiency. According to a report by Technavio, companies employing hydraulic cutting presses have achieved up to a 30% reduction in production time, attributed to the machines' superior force and precision. This efficiency not only optimizes resource utilization but also significantly minimizes material waste, which is critical in today's sustainability-focused manufacturing landscape.

In the textile industry, a leading manufacturer demonstrated the effectiveness of hydraulic cutting presses by integrating them into their operations. The company reported a 25% increase in output alongside a reduction in labor costs, as the automation capabilities of these presses reduce the need for manual intervention. Such data illustrates the dual benefits of adopting advanced hydraulic technologies: higher productivity and lower operational costs. As manufacturers embrace these innovations, it becomes evident that hydraulic cutting presses are set to redefine standards across various sectors, driving a surge in both efficiency and profitability.

The future of hydraulic cutting press technology promises significant advancements that will redefine manufacturing efficiency. As industries evolve, the need for precision and agility in production processes is paramount. Automation and smart technology integration will play crucial roles in enhancing the capabilities of hydraulic cutting presses. These innovations will not only streamline operations but also reduce human error, leading to higher quality outputs and minimized waste.

Moreover, the emphasis on sustainability will drive further developments in hydraulic pressing systems. Manufacturers are increasingly seeking energy-efficient machines that minimize environmental impacts without sacrificing performance. The incorporation of IoT technologies will enable real-time monitoring and predictive maintenance, ensuring optimal operation and reducing downtime. With these trends on the horizon, the hydraulic cutting press is set to become an indispensable tool in achieving lean manufacturing and fostering competitive advantages in the marketplace.