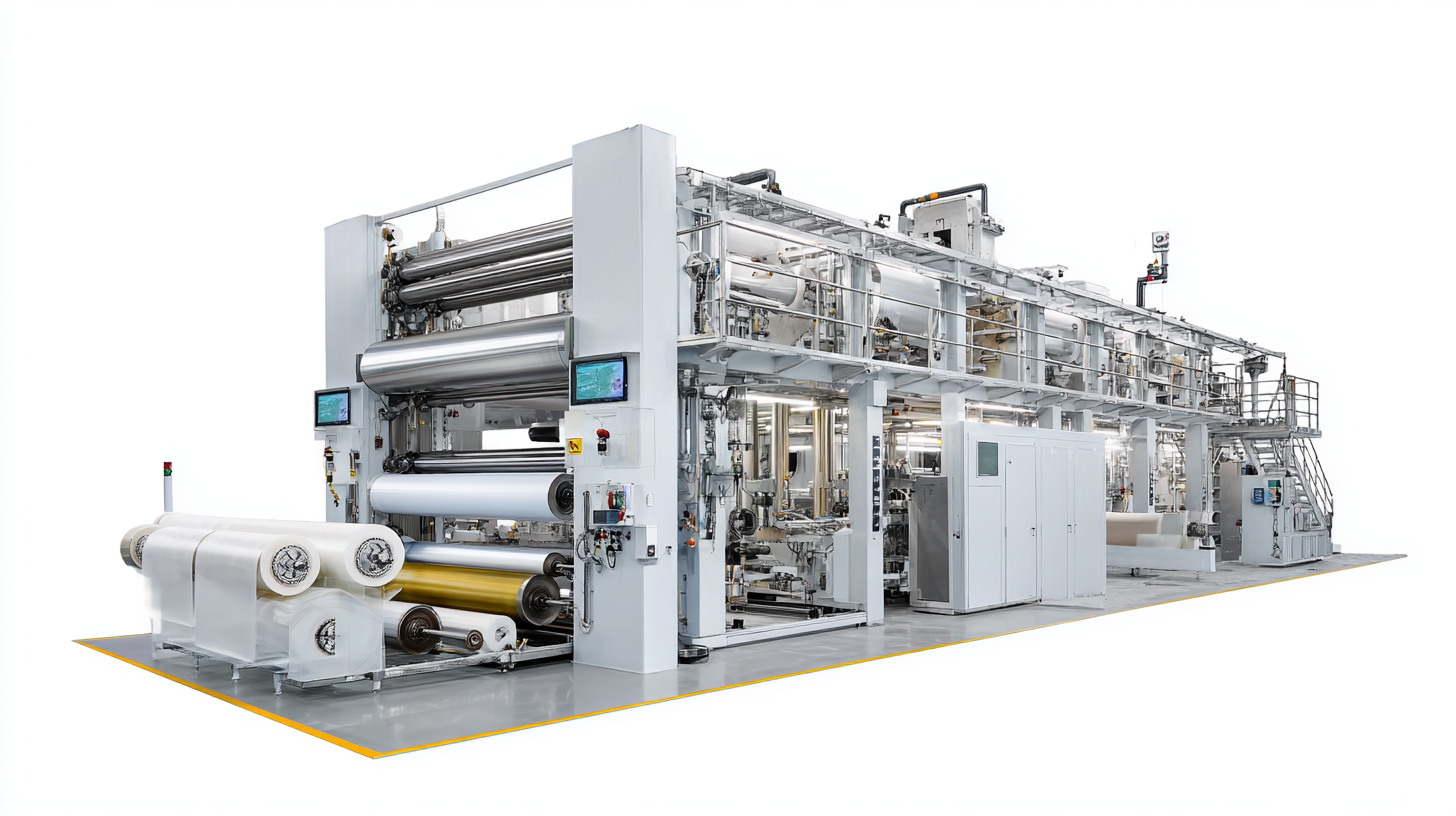

In the competitive landscape of manufacturing, optimizing your Coating Lamination Machine is essential for maximizing efficiency and productivity. According to a recent report by Smithers Pira, the global market for coating and laminating technologies is projected to grow at a CAGR of 4.1% over the next five years, driven by increasing demand for superior quality and sustainable packaging solutions. Effective utilization of Coating Lamination Machines not only enhances production rates but also reduces waste and operational costs. As processes become more intricate and technology advances, understanding the nuances of machine optimization has never been more critical. This guide will delve into strategic methodologies to fine-tune your Coating Lamination Machine, ensuring you stay ahead in an ever-evolving industry.

When optimizing your coating lamination machine, it's crucial to identify and monitor key performance indicators (KPIs) that directly impact efficiency. KPIs such as throughput, material waste percentage, and machine downtime provide valuable insights into the machine's operation. By focusing on these metrics, operators can pinpoint areas for improvement and enhance the overall productivity of their processes.

Tip: Regularly analyze your throughput by measuring the amount of product processed in a given time frame. This data will help you identify bottlenecks and streamline operations for better performance.

Reducing material waste is another essential KPI. Tracking waste generated during the lamination process allows for adjustments in parameters like speed and temperature. By minimizing waste, you not only cut costs but also increase sustainability, which is increasingly important in today’s manufacturing landscape.

Tip: Implement a feedback loop where operators can report inefficiencies related to material usage. This input can lead to actionable adjustments and foster a culture of continuous improvement.

Routine maintenance is essential for maximizing the efficiency of your coating lamination machine. Regular checks and adjustments keep the machine running smoothly, ultimately reducing downtime and improving production output. A good starting point is to establish a comprehensive maintenance schedule that includes daily, weekly, and monthly tasks tailored to your machine’s specific requirements.

Tips: Always inspect the rollers for wear and tear, as damaged rollers can lead to uneven application and product defects. Additionally, clean the machine’s parts regularly to remove any buildup of adhesive or dust, which can hinder performance. Pay special attention to the lubrication system; maintaining proper lubrication not only minimizes friction but also ensures that all components operate efficiently.

Another vital aspect of maintenance is software updates and calibration. Ensure that your machine’s software is up to date to benefit from the latest performance enhancements. Regularly calibrate sensors and automated controls, which can help you maintain precise operations and prevent costly errors. By integrating these maintenance practices into your routine, you can significantly enhance the efficiency of your coating lamination machine.

| Maintenance Task | Frequency | Expected Benefits | Impact on Efficiency |

|---|---|---|---|

| Clean rollers and plates | Weekly | Improves coating quality | High |

| Lubricate moving parts | Monthly | Reduces wear and tear | Medium |

| Inspect electrical connections | Quarterly | Prevents electrical failures | High |

| Calibrate sensors | Biannually | Ensures accuracy | High |

| Replace worn out parts | As needed | Increases operational life | Very High |

Optimizing temperature and pressure settings in coating lamination machines is crucial for enhancing efficiency and obtaining high-quality results. According to a report by the International Journal of Coating Technology, improper temperature settings can lead to adhesive failure, resulting in a significant increase in production costs—potentially up to 30%. For most adhesives used in lamination processes, maintaining a temperature range between 75°F to 120°F is essential to achieve optimal adhesion without compromising the material integrity.

Pressure also plays a vital role in ensuring uniform bonding during the lamination process. Research from the Coating and Laminating Institute indicates that increasing pressure to a threshold of 50 psi can significantly enhance the bond strength, improving durability and reducing the likelihood of product failure. However, exceeding recommended pressure levels may warp or damage the substrates, leading to waste and inefficiencies. Therefore, a careful balance of both temperature and pressure settings is necessary. Regularly comparing actual performance data against these optimized parameters can lead to continuous improvement, ensuring that the lamination process is both cost-effective and produces superior results.

This chart illustrates the relationship between temperature settings and pressure settings in optimizing the efficiency of coating lamination machines. A higher temperature can often lead to better adhesion, but must be balanced with pressure settings to avoid defects.

Training operators on best practices for effective laminating is crucial for optimizing the performance of coating lamination machines. Operators must be well-versed in the specific functions and capabilities of the machinery they are using. This includes understanding the types of materials involved, adjusting temperature and pressure settings appropriately, and recognizing the importance of consistent feed rates. Regular training sessions can help reinforce these skills, ensuring that operators can quickly troubleshoot issues and maintain machine efficiency.

Training operators on best practices for effective laminating is crucial for optimizing the performance of coating lamination machines. Operators must be well-versed in the specific functions and capabilities of the machinery they are using. This includes understanding the types of materials involved, adjusting temperature and pressure settings appropriately, and recognizing the importance of consistent feed rates. Regular training sessions can help reinforce these skills, ensuring that operators can quickly troubleshoot issues and maintain machine efficiency.

Moreover, fostering an environment of continuous learning can lead to significant improvements in laminating outcomes. Engaging operators in hands-on training and simulations can help them develop a deeper understanding of the laminating process. Workshops that focus on common challenges, such as air pockets or misalignment, will equip them with the tools needed to identify and rectify these issues before they lead to production delays. By prioritizing operator training, facilities can enhance their overall laminating quality and reduce waste, ultimately contributing to a more efficient and sustainable manufacturing process.

Implementing automated controls in your coating lamination machine can significantly enhance its efficiency and consistency. Automation minimizes human error and allows for precise adjustments in real-time, ensuring uniform coating thickness and optimal adhesion. By integrating sensors and feedback mechanisms, operators can monitor critical parameters like temperature and pressure, making necessary adjustments without downtime. This not only maintains quality but also speeds up the production process, making your operations more efficient.

Implementing automated controls in your coating lamination machine can significantly enhance its efficiency and consistency. Automation minimizes human error and allows for precise adjustments in real-time, ensuring uniform coating thickness and optimal adhesion. By integrating sensors and feedback mechanisms, operators can monitor critical parameters like temperature and pressure, making necessary adjustments without downtime. This not only maintains quality but also speeds up the production process, making your operations more efficient.

Tips for optimizing your automated controls include regularly updating software to ensure the latest features and improvements are utilized. Additionally, conduct routine maintenance of sensors to ensure they are calibrated correctly and functioning well. Encourage continuous training for operators to maximize their understanding of the automated system, allowing them to troubleshoot minor issues before they escalate.

Moreover, consider implementing predictive maintenance techniques by analyzing machine performance data to foresee potential equipment failures. This proactive approach reduces unplanned downtime and enhances the overall durability of your coating lamination machine, further boosting efficiency and productivity in your manufacturing process.