In the rapidly evolving landscape of manufacturing and industrial processes, the demand for efficient and high-quality solutions has never been more critical. One area gaining significant attention is the Thermohydraulic Coating Automatic Cutting process, which offers unparalleled precision and efficiency in material handling and preparation. According to a recent market analysis, the global market for automatic cutting solutions is projected to grow at a CAGR of 7.5% over the next five years, underscoring the increasing reliance on advanced technologies in production lines. As manufacturers strive to optimize their operations, identifying top suppliers who specialize in Thermohydraulic Coating Automatic Cutting is essential for ensuring quality and innovation. This blog will explore key strategies for sourcing the best suppliers, leveraging industry insights and professional reports to guide businesses in making informed decisions in this critical area.

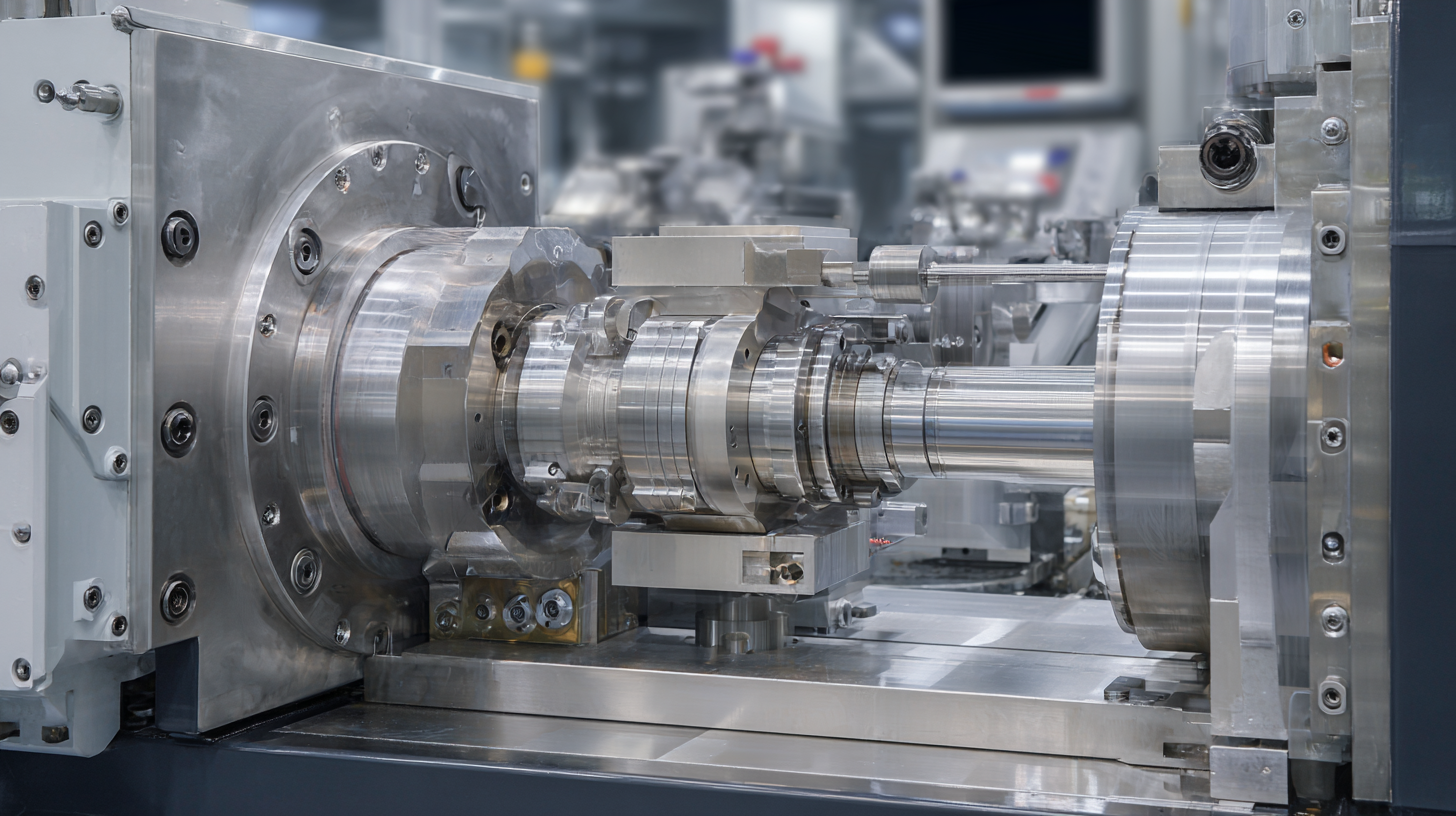

The significance of thermohydraulic coating in automatic cutting solutions cannot be overstated. This advanced coating technology enhances the performance and longevity of cutting tools by providing superior resistance to wear and thermal stress. In an industry where precision and efficiency are paramount, the durability offered by thermohydraulic coatings can lead to significant reductions in downtime and maintenance costs. As manufacturers focus on optimizing their production processes, integrating these coatings into their automatic cutting solutions proves to be a wise investment.

Moreover, the application of thermohydraulic coating not only improves tool life but also enhances cutting precision. By reducing friction and heat generation during the cutting process, operators can achieve smoother finishes and tighter tolerances, which are crucial for industries demanding high-quality outputs. As businesses strive to maintain competitiveness, understanding the benefits of thermohydraulic coatings will guide them in selecting top suppliers who can provide cutting-edge solutions tailored to their specific operational needs. Embracing these innovative technologies can ultimately lead to more efficient production workflows and enhanced product quality.

When searching for top suppliers of thermohydraulic coating automatic cutting solutions, it's essential to focus on a few key features that can significantly impact the efficiency and quality of your operations. According to a recent Market Research Future report, the global thermohydraulic coatings market is projected to grow at a CAGR of over 8% from 2021 to 2027, highlighting the increasing demand for reliable suppliers.

Firstly, evaluate the supplier's technology and innovation capabilities. Advanced thermohydraulic coating solutions rely on cutting-edge technology, and suppliers that invest in R&D are more likely to provide high-performance products. Look for certifications and industry standards, such as ISO 9001, as these can indicate a commitment to quality and innovation.

Tip: Always ask for case studies or client testimonials that demonstrate a supplier's experience in automating cutting solutions for thermohydraulic coatings. This can give you insight into their reliability and customer satisfaction.

Secondly, assess the supplier's customer service and support infrastructure. A supplier that offers comprehensive training and after-sales support can make a significant difference in the successful implementation of solutions. A well-established supplier should have a dedicated team for troubleshooting and ongoing technical assistance.

Tip: Consider scheduling a demo or site visit to better understand the supplier's operations and the performance of their equipment. This hands-on experience can be invaluable in your decision-making process.

When evaluating quality assurance in thermohydraulic coating solutions, it is essential to adhere to established industry standards. The recent discussions around food contact materials in Europe and North America highlight the importance of regulatory compliance as a cornerstone of quality assurance. Ensuring that suppliers meet these rigorous standards not only guarantees the safety and durability of their products but also aligns with global expectations for high-quality manufacturing.

The emphasis on smart manufacturing standards, as illustrated by initiatives from national bodies, reflects a significant shift towards a more structured approach in the industry. By investing in suppliers who prioritize these standards, businesses can ensure their coating solutions are not only effective but also sustainable and compliant with the latest regulations. This alignment not only enhances product performance but also fosters long-term partnerships, contributing to a robust and reliable supply chain in the field of thermohydraulic coating technologies.

When identifying top suppliers for thermohydraulic coating technologies, a comparative analysis of leading coating methods reveals critical insights into their microstructural properties and performance characteristics. Recent studies have demonstrated that Ti-enhanced AlCoCrFeNiTix coatings produced by laser cladding exhibit superior mechanical properties when compared to those generated by traditional techniques, primarily due to the reduced size of the B2 phase, which typically obstructs strength attainment in conventional coatings.

Further investigations into laser cladding methodologies have highlighted the performance differences between various techniques. For instance, Ni60 coatings achieved notably better cracking resistance when fabricated using annular laser cladding, thanks to a more uniform temperature distribution and gentler stress concentrations. This analytical comparison is crucial for suppliers looking to leverage the most effective coating solutions tailored to specific operational demands. Moreover, secondary studies on high entropy alloy coatings underscore the importance of fabrication methods, where high-speed laser cladding (HS-) outperformed normal methods in terms of microstructural integrity and coating properties.

These advancements in thermohydraulic coatings not only emphasize the need for suppliers to adopt innovative technologies but also indicate a shift towards leveraging comparative analyses for improving material qualities and application efficacy.

| Supplier Type | Technology Type | Efficiency (%) | Surface Finish Quality (Ra µm) | Cost per Unit ($) | Lead Time (Days) |

|---|---|---|---|---|---|

| Supplier A | Electron Beam Coating | 95 | 0.3 | 2500 | 30 |

| Supplier B | Plasma Coating | 90 | 0.4 | 2200 | 25 |

| Supplier C | Thermal Spray Coating | 85 | 0.5 | 1800 | 20 |

| Supplier D | Chemical Vapor Deposition | 88 | 0.2 | 3000 | 35 |

| Supplier E | Arc Spray Coating | 80 | 0.6 | 1600 | 15 |

In the dynamic coating industry, collaborating with top suppliers is essential for achieving the best thermohydraulic coating automatic cutting solutions.

One of the best practices involves establishing clear communication channels. Regular updates and open discussion around product specifications and delivery timelines ensure both parties are aligned, ultimately leading to enhanced efficiency.

Moreover, assessing suppliers' compliance with environmental standards can significantly impact sustainability efforts, especially in sectors like shipbuilding where coatings must combat biofouling.

Additionally, utilizing industry events and conferences can provide valuable networking opportunities. Engaging with industry leaders and participating in collaborative initiatives fosters a community focused on innovation and best practices.

For instance, recent partnerships formed in the maritime sector highlight the growing importance of collective efforts to address challenges such as environmental impact.

By leveraging these connections and shared knowledge, organizations can enhance their supplier relationships, leading to more effective and sustainable coating solutions.