The Ud Impregnation Machine is rapidly transforming the manufacturing landscape, driven by a wave of innovative technologies and approaches that enhance productivity and efficiency. According to a recent report by MarketsandMarkets, the global composite materials market, which heavily relies on impregnation technologies, is projected to reach $33.5 billion by 2025, growing at a CAGR of 10.5%. This growth is fueled by the increasing demand for lightweight materials in industries such as aerospace, automotive, and construction.

As manufacturers increasingly adopt automation and advanced processing techniques, the Ud Impregnation Machine stands at the forefront of this evolution, integrating cutting-edge developments such as IoT connectivity and real-time monitoring capabilities. These innovations not only optimize production workflows but also enable a higher degree of customization and sustainability in manufacturing processes, marking a significant shift in how industries achieve operational excellence and meet the demands of a competitive global market.

Innovations in Ud impregnation machines are poised to

revolutionize the manufacturing landscape, echoing trends observed in healthcare technologies. Just as the advent of

affordable, at-home ultrasound devices is transforming prenatal care, advanced materials and automation in Ud impregnation processes are enhancing

efficiency and precision in production. According to recent industry reports, the global market for impregnation

technologies is expected to grow at a CAGR of over 7% from 2023 to 2030, driven by increasing demand for

sustainable materials and optimized manufacturing solutions.

As industries adopt more sophisticated impregnating techniques, manufacturers can achieve

higher quality and reduced waste. Tips for embracing these innovations include investing in training for personnel

to properly operate new machinery and integrating data analytics for real-time monitoring of production efficiency.

Additionally, collaborating with technology providers can help secure custom solutions tailored

to specific manufacturing needs.

The momentum gained from innovations such as AI-enabled ultrasound devices and the development of

composite machinery signals a transformative era for Ud impregnation machines. By leveraging cutting-edge

technologies, businesses can not only enhance their operational capabilities but also contribute to a more

sustainable and competitive manufacturing sector. Keeping abreast of these advancements is critical for organizations

aiming to lead in their industry.

As the manufacturing industry evolves, the push for sustainability has never been more critical. In recent years, innovations in ud impregnation machines have begun integrating eco-friendly materials, paving the way for greener manufacturing processes. These machines are now designed to utilize biodegradable resins and recycled composites, reducing waste and minimizing the environmental footprint of production. This shift not only helps in conserving natural resources but also meets the growing consumer demand for sustainable products.

Furthermore, manufacturers are exploring alternative energy sources to power ud impregnation machines, such as solar and wind energy. This transition to renewable energy not only lowers operational costs but also curtails the reliance on fossil fuels, aligning with global sustainability goals. By adopting these innovations, companies can enhance their brand reputation and appeal to environmentally conscious consumers, thus placing themselves at the forefront of a rapidly changing manufacturing landscape.

The future of ud impregnation is not just about efficiency and productivity; it’s about fostering a resilient and sustainable industry for generations to come.

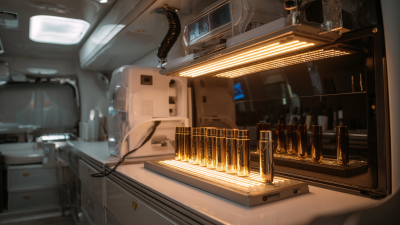

The landscape of Ud impregnation processes is being transformed by automation, which significantly enhances efficiency and precision. As manufacturers look to streamline operations and minimize human error, the integration of automated systems becomes increasingly vital. Sophisticated machinery equipped with advanced sensors and artificial intelligence allows for real-time monitoring and adjustment during the impregnation process, ensuring optimal performance and consistency across batches. This shift not only accelerates production times but also improves the overall quality of the final product.

Moreover, automation fosters greater flexibility in manufacturing. With programmable settings, machines can easily adapt to varying specifications and product types without extensive retooling. This agility is particularly advantageous in today’s fast-paced market, where customization and quick turnaround times are essential.

By harnessing automation, manufacturers can respond promptly to changing demands while maintaining rigorous quality standards, ultimately reshaping the competitive landscape of Ud impregnation technology.

The landscape of global manufacturing is rapidly evolving, with digital integration taking center stage in the development of UD impregnation systems. As industries seek to enhance efficiency and reduce downtime, the adoption of smart manufacturing technologies has become a necessity. These advancements enable real-time monitoring and data analysis, allowing manufacturers to optimize processes and predict maintenance needs proactively. The integration of IoT devices within impregnation machines facilitates improved communication between systems, creating a more synchronized production environment.

Additionally, innovations in software applications are transforming how manufacturers interact with their UD impregnation machines. Advanced algorithms can analyze production data, leading to better decision-making and more streamlined operations. With features like automated quality checks and workflow management, businesses are not only able to meet strict quality standards but also adapt quickly to changes in production demands. As digital technologies continue to advance, the future of UD impregnation machines promises greater adaptability and efficiency in manufacturing practices, setting a new standard for the industry.

In recent years, traditional impregnation methods in manufacturing have faced significant challenges, prompting the industry to explore alternative techniques. Conventional approaches often fall short in terms of efficiency, environmental impact, and adaptability to new materials. As manufacturers seek to enhance product quality and streamline processes, innovative impregnation methods are emerging as viable solutions. These techniques not only improve material properties but also reduce waste and energy consumption, aligning with global sustainability goals.

One noteworthy advancement in this domain is the integration of advanced technologies, such as ultrasonic and vacuum-assisted impregnation. These methods allow for deeper penetration of resin into materials, ensuring a more uniform finish and greater durability. Additionally, innovations like 3D printing with impregnation capabilities are revolutionizing the manufacturing landscape, enabling the creation of complex geometries that were previously unachievable. By embracing these alternative techniques, manufacturers can challenge the status quo, ultimately leading to more efficient production processes and superior end-products that meet contemporary consumer demands.