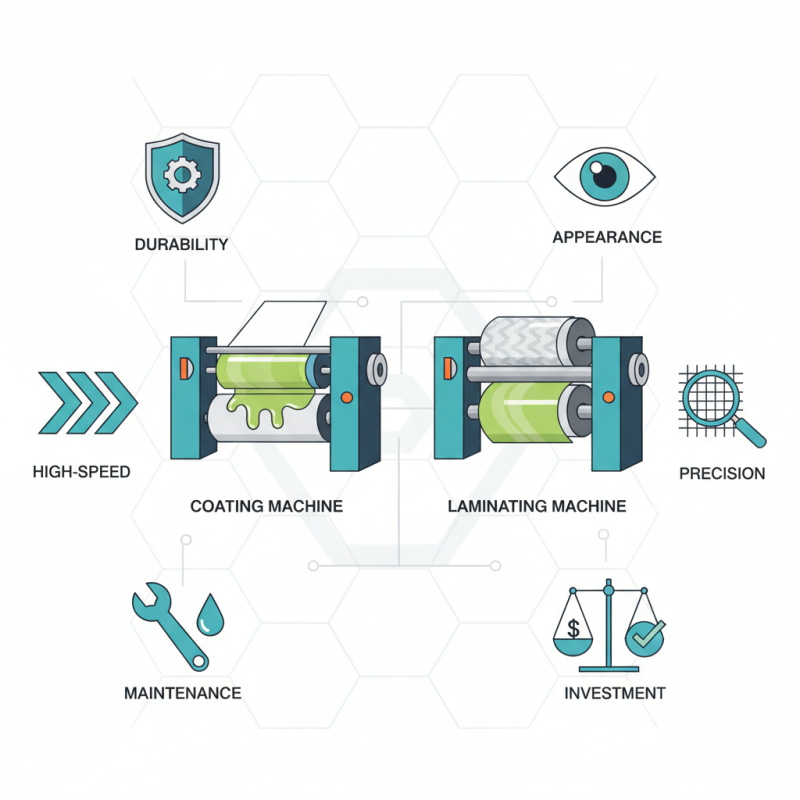

Coating and laminating machines play a pivotal role in modern manufacturing. These machines enhance product durability and appearance. They can apply protective coatings, adhesives, or films to various materials. Understanding their functions is essential for businesses aiming for quality production.

These machines come in various types, each designed for specific tasks. Some are suitable for high-speed applications, while others focus on precision. Investing in the right coating and laminating machines can significantly impact a company's efficiency. However, the choice often brings challenges and requires careful consideration.

Many users overlook maintenance details, which can affect performance. Regular checks on parts are essential for longevity. Companies must also weigh the benefits against potential costs. Therefore, knowing the ins and outs of coating and laminating machines is crucial for success in this competitive landscape.

Coating and laminating machines are essential in various industries. They enhance the durability and appearance of materials. These machines apply thin layers of protective coatings or films. This process can improve resistance to moisture, chemicals, and wear.

Understanding the difference between coating and laminating is crucial. Coating typically involves spraying or rolling a liquid to create a hard surface. Laminating, on the other hand, bonds layers together using heat or pressure. Knowing when to use each method can affect quality. Choosing the wrong approach may lead to weak adhesion.

Operators must also consider machine settings. Incorrect adjustments can result in uneven application. This might spoil entire batches. Regular maintenance is essential to ensure optimal performance. Neglecting upkeep could lead to costly downtime. Balancing efficiency with precision is key in this field.

Coating and laminating machines are essential in various industries, including packaging, textiles, and printing. Different types of machines serve specific purposes. For example, roll-to-roll laminating machines apply a protective film to rolls of material. This method enhances durability and visual appeal.

Another common type is the flatbed coater, ideal for applying coatings on sheets. These machines ensure even distribution of materials and are useful in paper production. However, it’s important to recognize that not all machines can handle every type of material. Some may struggle with thicker substrates, leading to unsatisfactory results.

Understanding the applications of each machine type is crucial. For instance, some may excel in speed but suffer in precision. Others might provide superior quality, but at a slower pace. Users must evaluate their needs carefully. Not every machine is perfect for every job. Finding the right balance between speed, quality, and material compatibility often requires trial and error. This complexity adds to the learning curve in the coating and laminating process.

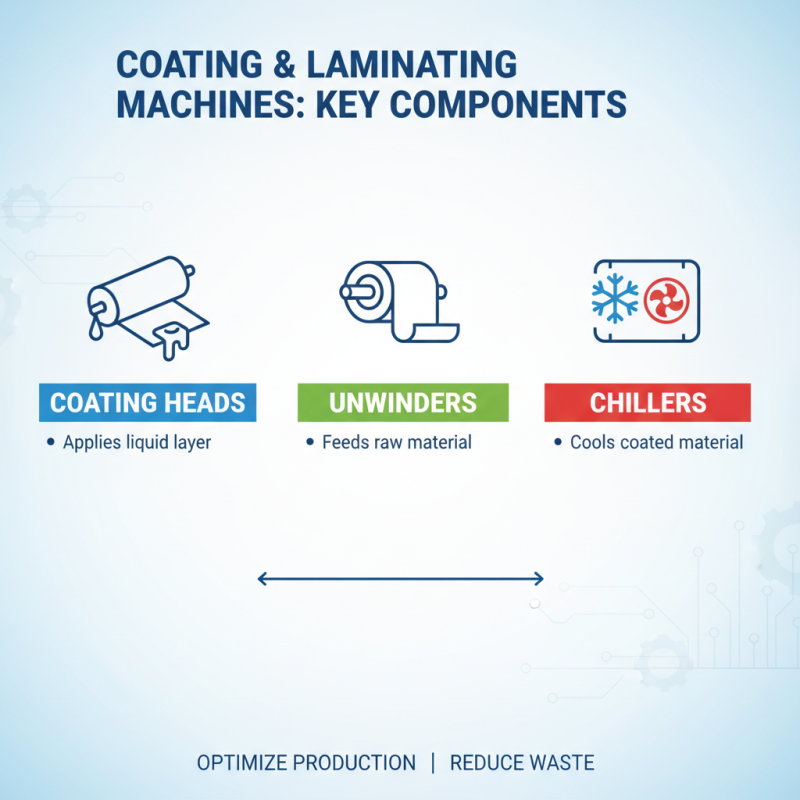

Coating and laminating machines are vital in many industries. Understanding their key components helps optimize processes. These machines typically include several essential parts: coating heads, unwinders, and chillers.

Coating heads apply various materials onto substrates. They can be adjustable to accommodate different thicknesses. This flexibility can be a double-edged sword; too much adjustment can lead to inaccuracies. Unwinders feed the material into the machine. They must operate smoothly to avoid jams and inconsistencies. If they fail, production will halt.

Chillers maintain the proper temperature during the process. They ensure uniform drying and adhesion. However, if the temperature fluctuates, it can spoil the final product. Operators often overlook regular maintenance, leading to breakdowns. Each component plays a crucial role, but operators must be vigilant. Minor issues can escalate quickly, causing significant setbacks.

Maintaining coating and laminating machines is crucial for safety and performance. Regular inspections can catch issues before they escalate. Operators should check the belts and rollers for wear and tear. A worn belt may slip, causing uneven application. Lubricating the moving parts reduces friction and wear. Dirty or jammed components can also lead to breakdowns. Clean the machine daily to prevent buildup.

Safety is paramount when operating these machines. Protective gear, like gloves and goggles, is essential. Operators should be trained on emergency shut-off procedures. Accidents can happen quickly if safety protocols are ignored. Even small oversights can be costly. Always check the emergency stops before starting the machine.

It's vital to document maintenance activities. Record keeping provides insights into the machine's performance over time. Tracking repairs can help anticipate future issues. Operators often overlook this aspect. Neglecting documentation can lead to unexpected breakdowns, resulting in delays. Machines need attention; patience and diligence are key.

Recent innovations in coating and laminating technology are reshaping the industry. According to a recent study by Markets and Markets, the global market for coating and laminating machines is projected to grow at a CAGR of 4.5% from 2023 to 2028. This growth is fueled by increased demand for protective and functional coatings in various sectors, such as packaging and textiles.

New techniques, such as water-based coatings and UV curing, are gaining traction. Water-based coatings are more environmentally friendly, emitting fewer volatile organic compounds. They play a crucial role in sustainable manufacturing. However, the challenge remains in achieving the same performance as solvent-based alternatives. Companies are often left pondering how to balance ecological responsibility with product quality.

Automation is another trend driving change. It enhances efficiency and reduces labor costs. Robotics and AI are becoming more prevalent in coating and laminating processes. Yet, the integration of these technologies can come with a steep learning curve for workers. Training is essential, but many companies struggle to keep up with rapid advancements. This gap can hinder the potential benefits of new technologies if not addressed properly.