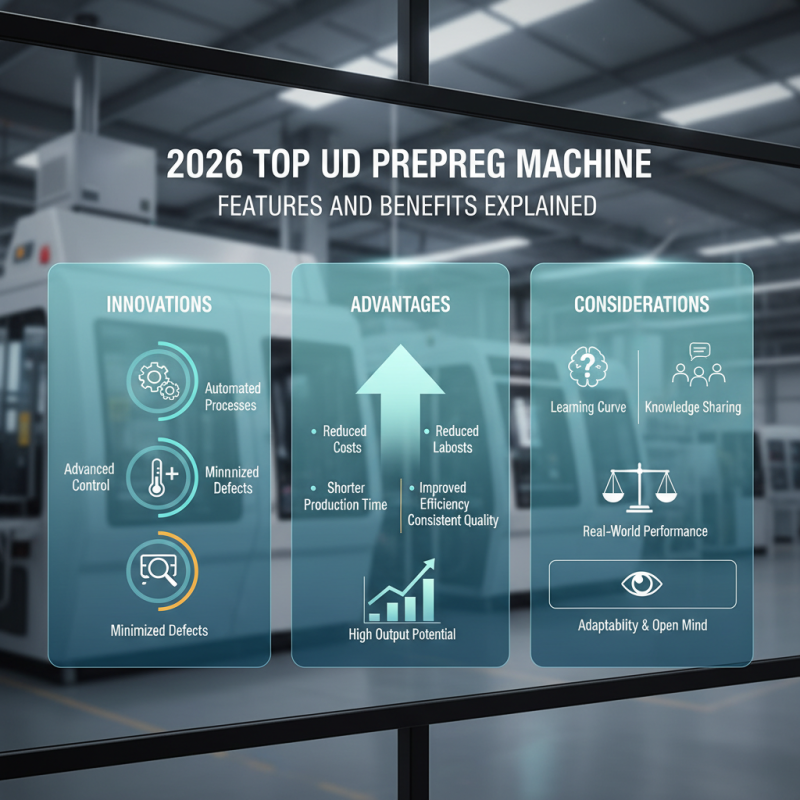

The Ud Prepreg Machine is revolutionizing the composite manufacturing industry. Designed for precision, it offers exceptional benefits that improve production efficiency. In 2026, we expect even more advanced features, enhancing its capabilities.

This machine excels in the automation of prepreg processes, reducing labor costs and time. With features like advanced temperature control, it ensures optimal curing conditions. Such specificity minimizes defects, a key concern for manufacturers. However, challenges remain. While user-friendly, some operators may find the learning curve steep.

Investing in a Ud Prepreg Machine requires careful consideration. It promises high output, but real-world performance can vary. The balance between cost and efficiency is not always straightforward. An open mind is essential when adapting to new tech. Knowledge sharing within teams can alleviate some of these bumps in the road.

The 2026 Top UD prepreg machines offer advanced features for composite manufacturing. One standout feature is the automatic tension control. This ensures consistent tension across the entire roll. Proper tension is crucial for high-quality results. Additionally, these machines often have precise temperature controls. This is vital, as the right temperature helps the resin cure correctly.

Operators might appreciate the user-friendly interface. A clear display can reduce errors during operation. However, potential users should consider their training needs. Without proper training, even the best machines can underperform. Integration with existing systems can pose challenges. Take the time to plan this process carefully.

Tips: Regular maintenance can maximize machine longevity. Checking parts regularly prevents unexpected downtimes. Moreover, always keep a log of machine performance. This tracking can help diagnose issues early on. Mistakes happen, and reflecting on them is key for improvement.

Using UD prepregs in manufacturing offers significant advantages. These materials feature excellent mechanical properties and high strength-to-weight ratios. Recent data indicates that UD prepregs can reduce weight by up to 30% compared to traditional materials. This weight reduction is crucial in aerospace and automotive industries, where efficiency is essential.

The process of using UD prepregs also enhances manufacturing efficiency. They allow for faster curing times and less waste due to their precise fiber orientation. According to a report from a manufacturing association, the integration of UD prepregs can lead to a 20% decrease in production time. However, implementing these materials requires careful handling and attention to detail, which can pose challenges for manufacturers.

Another benefit is the ability to customize the prepregs according to specific needs. This flexibility can meet various requirements in design. Yet, there’s a learning curve involved. Many manufacturers need time to adapt to this new material, which might slow initial production. The investment in training and equipment can yield long-term benefits. Balancing these factors is part of the ongoing process for many companies.

In 2026, advancements in UD prepreg machines have significantly transformed composite manufacturing. These machines now come equipped with auto-calibration features, ensuring precise handling of materials. According to industry reports, automation has reduced labor costs by nearly 30%. This technology allows for more consistent quality in the finished products.

Moreover, improved temperature control mechanisms facilitate better curing processes. These innovations enhance resin flow, which leads to superior bond strength in composites. A study revealed that better temperature management can increase production rates by up to 25%. Many manufacturers are now exploring eco-friendly materials. This shift meets growing demand for sustainable production practices.

Tip: Always perform regular maintenance checks. Simple issues can escalate quickly in complex machinery. Staying proactive saves time and costs.

However, not all companies have adapted to these changes. Some remain hesitant, fearing high initial costs. They risk falling behind competitors who embrace innovation. It’s vital to assess the long-term benefits versus immediate expenses. Frequent training sessions for staff also pose a challenge but are essential for maximizing the machine’s potential.

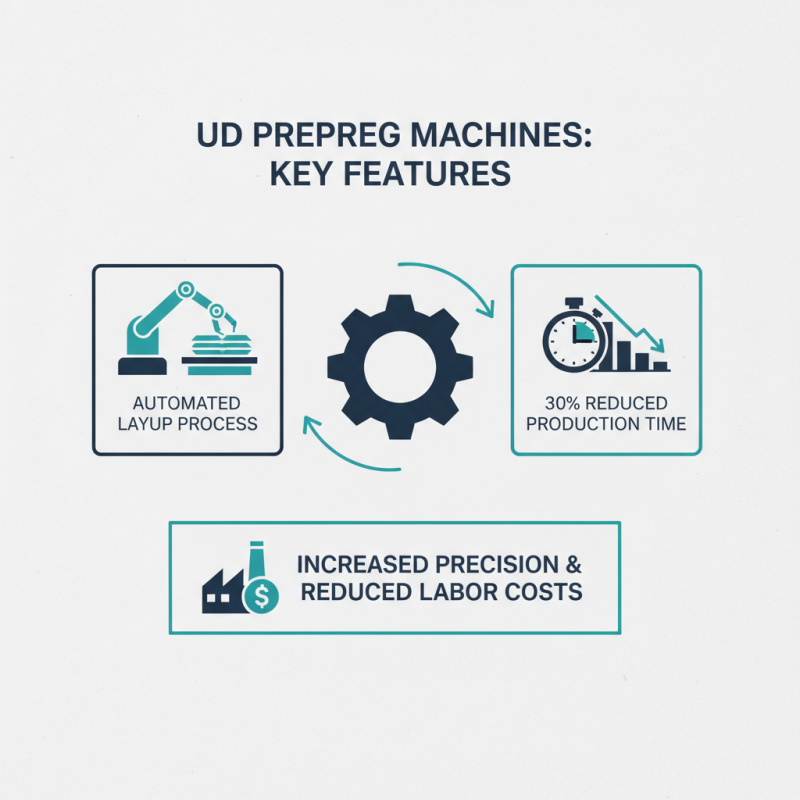

When examining the landscape of UD prepreg machines, a few key features stand out across various brands. Many top machines emphasize automated layup processes. This allows for increased precision and reduced labor costs, key factors in today’s competitive market. Recent industry reports indicate that automation in composite manufacturing can cut production times by up to 30%, making these machines attractive for manufacturers aiming for efficiency.

Additionally, these machines often incorporate advanced temperature control systems. Precise temperature management is crucial for the performance of prepreg materials. Inconsistent temperatures can lead to defects and inconsistencies, which can be costly in large production runs. Manufacturers have noted an increase in production yields, with some achieving rates over 90% due to better control over the process.

However, the technology comes with challenges. High initial investment costs can deter smaller firms from upgrading. Not every brand delivers uniform reliability; some may struggle with maintenance and downtime. This variability prompts a need for deeper analysis and consideration before making a purchase decision. Industry feedback highlights that while top brands may guarantee efficiency, the inconsistency in performance can be a significant drawback.

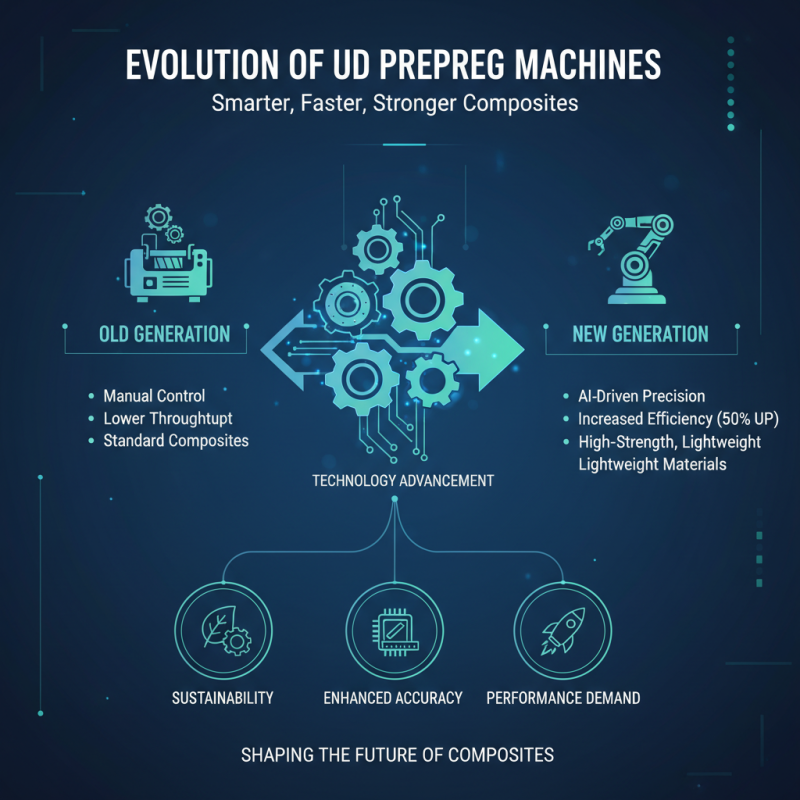

The future of UD prepreg machines is evolving rapidly. Technology is advancing to improve efficiency and precision. These machines are integral in producing lightweight, high-strength composite materials. As industries demand better performance, we see a shift in machine development.

Manufacturers focus on automation and smart technologies. These features enhance control and monitoring during the production process. The integration of AI will be key, helping to predict failures and optimize operations. However, it's essential to consider the challenges that come with these advancements. Adapting to new technologies can be overwhelming for some operators.

Tips for adapting to these changes: 1. Invest in training programs. Skilled operators can maximize the benefits of advanced machines. 2. Regularly review machine performance. This helps in identifying areas for improvement. The road ahead may have bumps, but companies that embrace these changes will thrive. The evolution of UD prepreg machines promises a more efficient and sustainable future in composite production.