Leave Your Message

As we approach 2025, the landscape of the Ud Fabric Production Line is poised for transformative changes that will redefine industry standards and operational efficiencies. Industry expert Dr. Emily Carter, a leading figure in textile technology, remarks, "The future of Ud Fabric Production Lines lies in the seamless integration of automation and sustainable practices." This foresight underscores the growing trend towards innovation and eco-conscious methods that are becoming essential in fabric production.

In the coming years, we anticipate several key trends that will shape the Ud Fabric Production Line, including advancements in automation, the adoption of eco-friendly materials, and enhanced production techniques. These trends not only aim to improve productivity but also align with the global push towards sustainability in manufacturing. As companies adapt to these changes, they will focus on reducing waste, optimizing resource utilization, and meeting the increasing consumer demand for environmentally responsible products.

Understanding these trends is critical for stakeholders across the industry, as they navigate the evolving landscape of the Ud Fabric Production Line. Embracing new technologies and sustainable practices will not only foster innovation but also ensure that companies remain competitive in a rapidly changing market. As we delve into these top trends, it becomes clear that the future of Ud Fabric Production Line is bright, offering opportunities for growth and enhancement that are vital for long-term success.

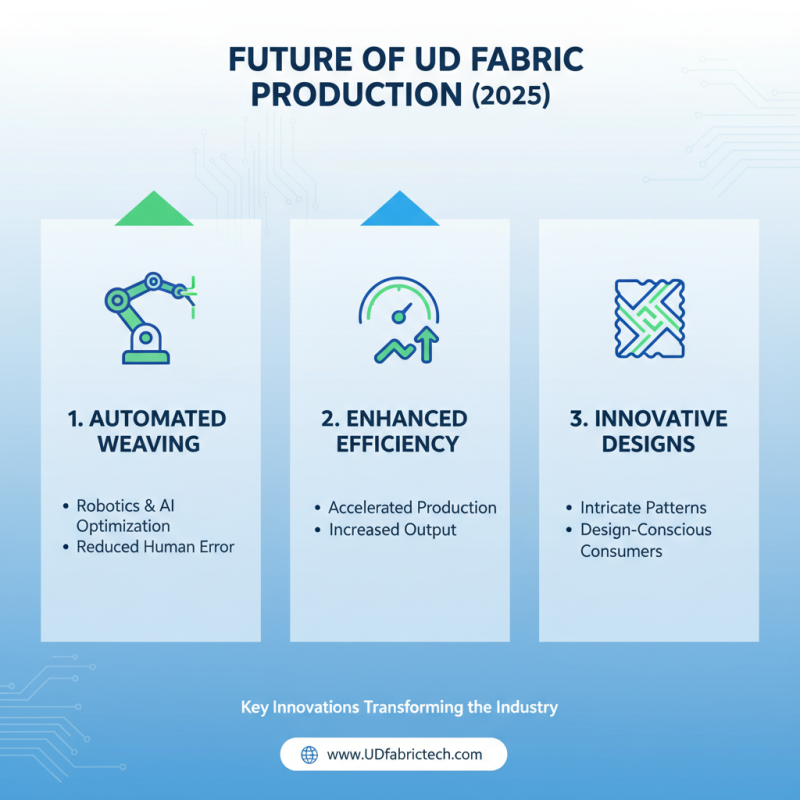

The landscape of Ud fabric production technology is evolving rapidly, with several key innovations expected to transform the industry by 2025. One significant advancement is the integration of automated weaving technologies. These systems utilize robotics and artificial intelligence to optimize the production process, reducing human error and increasing efficiency. Automation not only accelerates production times but also allows for more intricate designs and patterns, meeting the demands of a more design-conscious consumer base.

In addition to automation, advancements in sustainable materials are set to play a crucial role in Ud fabric production. The shift towards eco-friendly textiles is driving research into innovative fibers made from recycled plastics and natural resources. These sustainable materials not only minimize environmental impact but also enhance the durability and performance of the fabrics. As manufacturers adopt these greener alternatives, they are likely to appeal to a growing segment of consumers who prioritize sustainability, allowing them to stay competitive in an increasingly eco-conscious market.

Sustainability practices are becoming increasingly integral to the future of Ud fabric manufacturing, with emerging trends focused on reducing environmental impacts while enhancing product quality. Manufacturers are adopting eco-friendly raw materials, such as organic fibers and recycled plastics, to minimize reliance on non-renewable resources. By implementing a circular economy model, companies are finding innovative ways to recycle fabric waste and repurpose it into new products, thereby decreasing landfill contributions and energy consumption.

Additionally, energy-efficient production techniques are gaining traction, as manufacturers invest in technologies that lower carbon footprints. These include the use of renewable energy sources, such as solar and wind power, along with advancements in water conservation practices during the dyeing processes. By prioritizing sustainability in every stage of production—from sourcing to final product delivery—Ud fabric manufacturers not only meet growing consumer demand for eco-conscious products but also position themselves as leaders in responsible manufacturing practices. This holistic approach is essential for fostering a sustainable future in the textile industry.

The integration of automation and robotics in the production lines of UD (unidirectional) fabric is set to reshape the textile industry by 2025. A recent report from the Global Textile Automation Association indicates that the adoption of automated systems in fabric production is expected to increase efficiency by over 30%. This change is largely driven by the need for manufacturers to minimize human error, reduce labor costs, and enhance production speed. Automated cutting and sewing technologies are playing a pivotal role, as they allow for greater precision and consistency in fabric quality, which is crucial for industries such as aerospace and automotive that rely on high-performance UD fabrics.

Moreover, the rise of collaborative robots, or cobots, is another emerging trend that is transforming fabric production lines. According to data from TechNavio, the market for cobots in the textile sector is projected to grow by 25% annually through 2025. These robots are designed to work alongside human operators, handling repetitive tasks while allowing skilled workers to focus on more complex processes. This symbiotic relationship not only improves workplace safety but also enhances overall productivity. By leveraging advanced machine learning and AI, these robotic systems can adapt to changing production demands, ensuring that UD fabric manufacturers stay competitive in a rapidly evolving market.

As the demand for sustainable and innovative textile solutions continues to grow, the production of UD (Unidirectional) fabrics is shifting in response to market needs. By 2025, the global market for UD fabrics is projected to reach approximately $2.1 billion, driven largely by advancements in composite materials and increasing applications in aerospace and automotive industries. Reports indicate that about 40% of the demand will come from sectors focused on lightweight, high-strength materials, which are crucial for enhancing fuel efficiency and performance.

In light of these evolving market demands, manufacturers must invest in technology that enables better efficiency and higher precision in UD fabric production. Key trends include the integration of automation and IoT technologies, which can reduce production costs and minimize waste. Moreover, the emphasis on eco-friendly processes is becoming more pronounced; a recent study showed that 60% of consumers prefer products made from sustainable materials, providing a significant incentive for industries to adapt their production lines accordingly.

Tips: For companies looking to enhance their UD fabric production processes, consider implementing advanced analytics to optimize resource allocation and streamline workflows. Additionally, collaborating with research firms can provide insights into emerging trends and consumer preferences, ensuring that your production strategies stay ahead of the curve. Adopting a flexible production model will also enable manufacturers to respond quickly to shifting market demands, thus maintaining a competitive edge in an increasingly dynamic marketplace.

The integration of smart technologies in the UD fabric production processes is set to revolutionize the industry by 2025. As manufacturers strive for higher efficiency and lower operational costs, the adoption of automation and artificial intelligence (AI) is becoming increasingly prevalent. According to a report from Smithers Pira, the global smart textiles market is expected to reach $5 billion by 2024, highlighting a shift toward more intelligent manufacturing solutions. These innovations not only enhance productivity but also significantly improve quality control through real-time monitoring and predictive analytics.

Moreover, the implementation of the Internet of Things (IoT) in UD fabric production allows for seamless connectivity between machinery and production systems. This connectivity facilitates data collection that can lead to optimized processes and reduced waste. A study by Mordor Intelligence estimates that the IoT in manufacturing market will witness a growth rate of over 25% annually, underscoring the increasing reliance on interconnected devices to streamline production. By leveraging these smart technologies, manufacturers are poised to enhance their operational efficiency while meeting the growing demand for high-quality and sustainable UD fabrics.

| Trend | Description | Expected Impact | Implementation Year |

|---|---|---|---|

| Automation | Increase in production efficiency by automating manual tasks. | Improved throughput and reduced labor costs. | 2025 |

| AI Integration | Utilization of AI for quality control and predictive maintenance. | Reduced defects and downtime, enhancing overall quality. | 2025 |

| IoT Connectivity | Integration of IoT devices for real-time monitoring. | Enhanced visibility and control over manufacturing processes. | 2025 |

| Sustainability Practices | Adopting eco-friendly materials and processes. | Better environmental impact and compliance with regulations. | 2025 |